2024-09-09

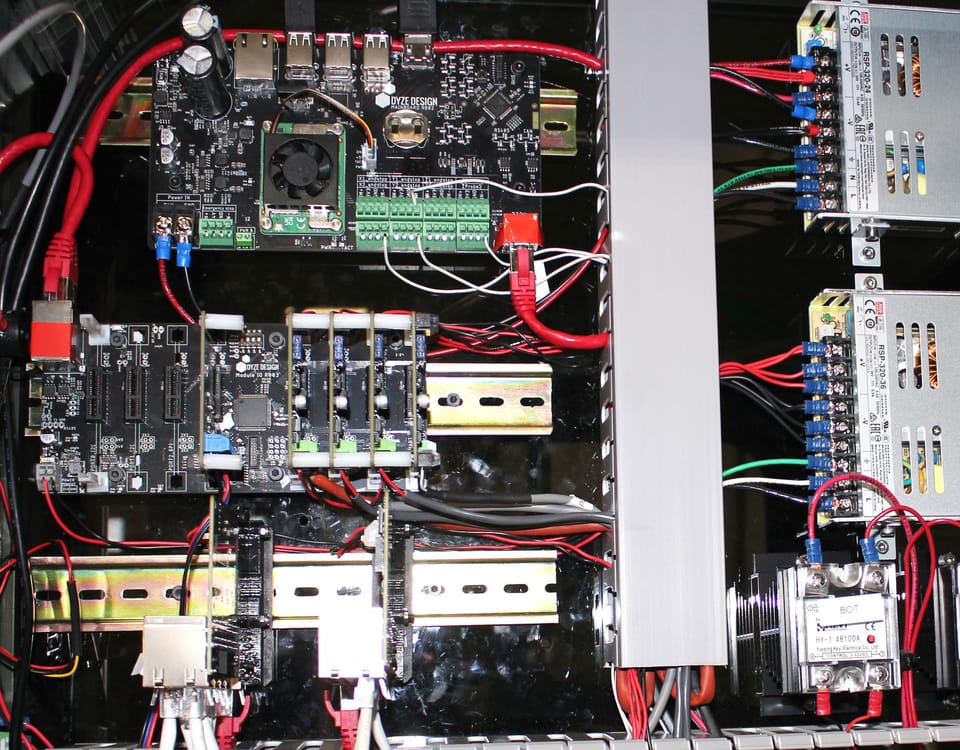

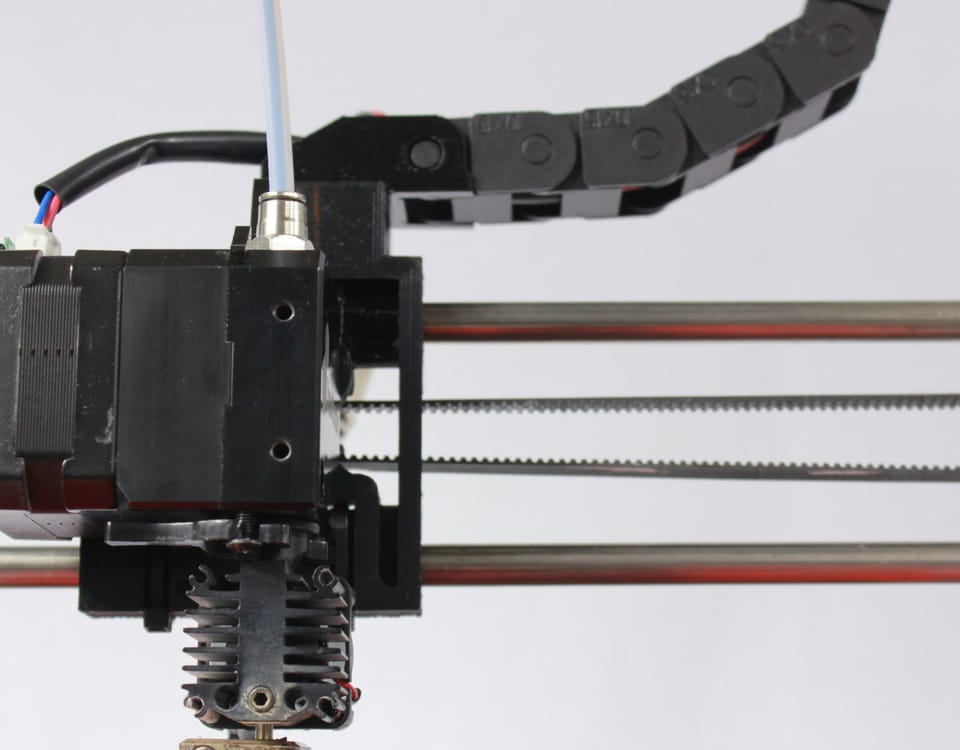

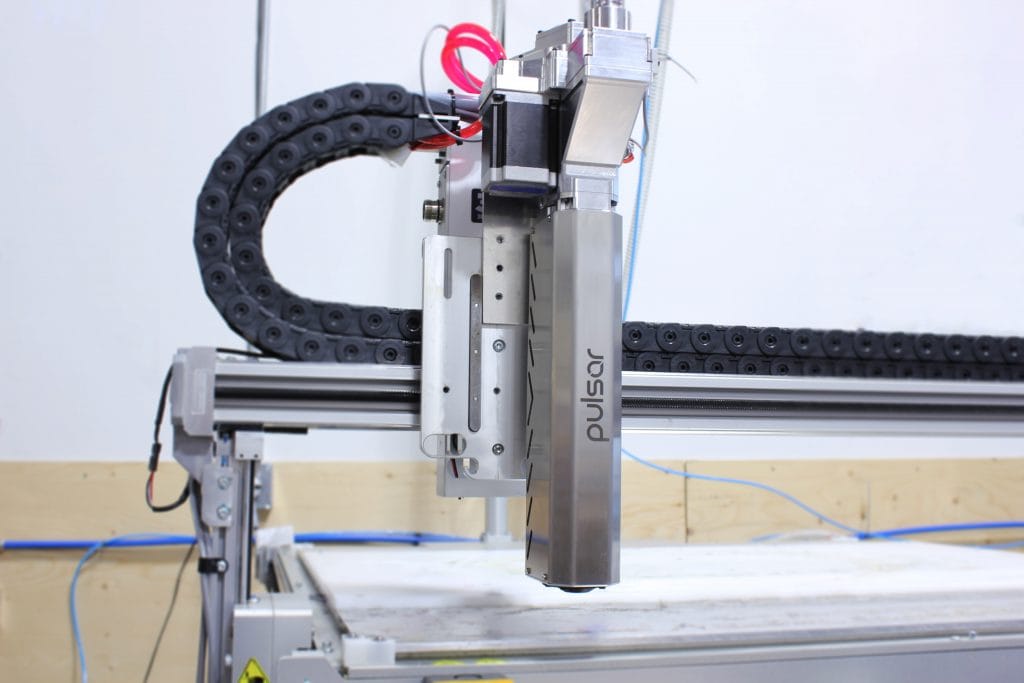

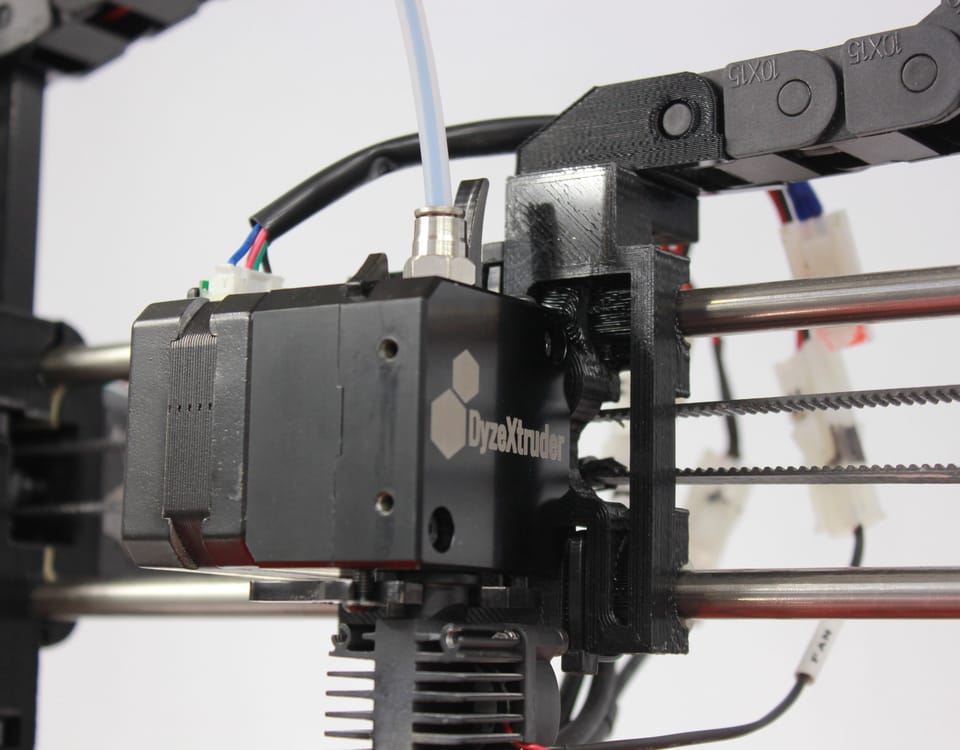

This strategic partnership aims to enhance precision, speed, and quality in 3D printed prosthetic sockets with Dyze Design’s new advanced industrial motion I/O controller. MONTREAL, QC, September 09, 2024 – Filament Innovations, a leading Pennsylvania-based OEM specializing in additive manufacturing […]