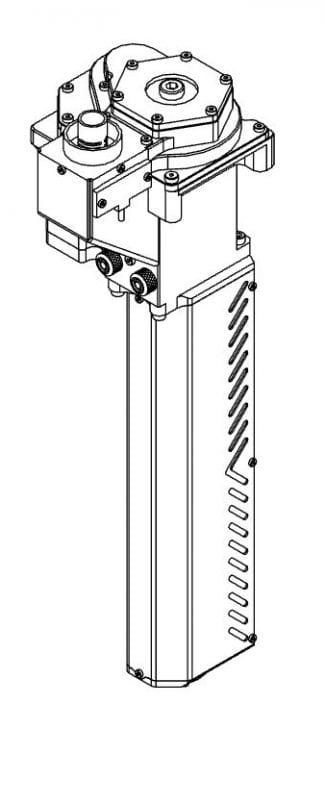

Pulsar™ Large-Scale Pellet Extruder

Save time.

Save costs.

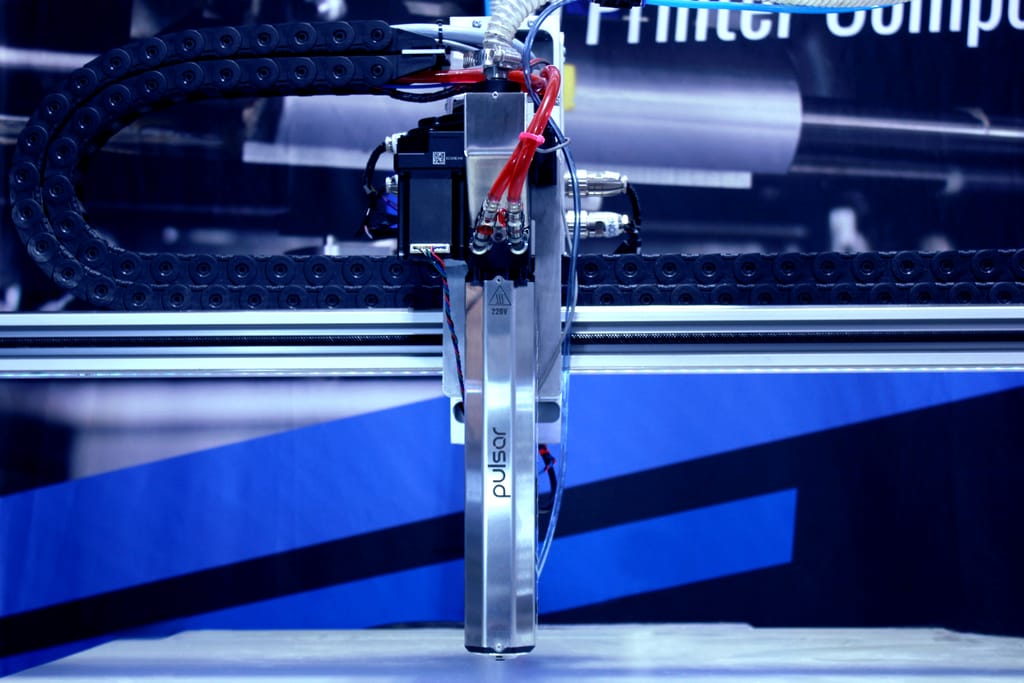

Pulsar™ is a state-of-the-art large-scale and high flow plastic pellet extruder.

It was designed with one purpose in mind: 3D printing of parts of one m³ and more as quickly and as cost-effective as possible.

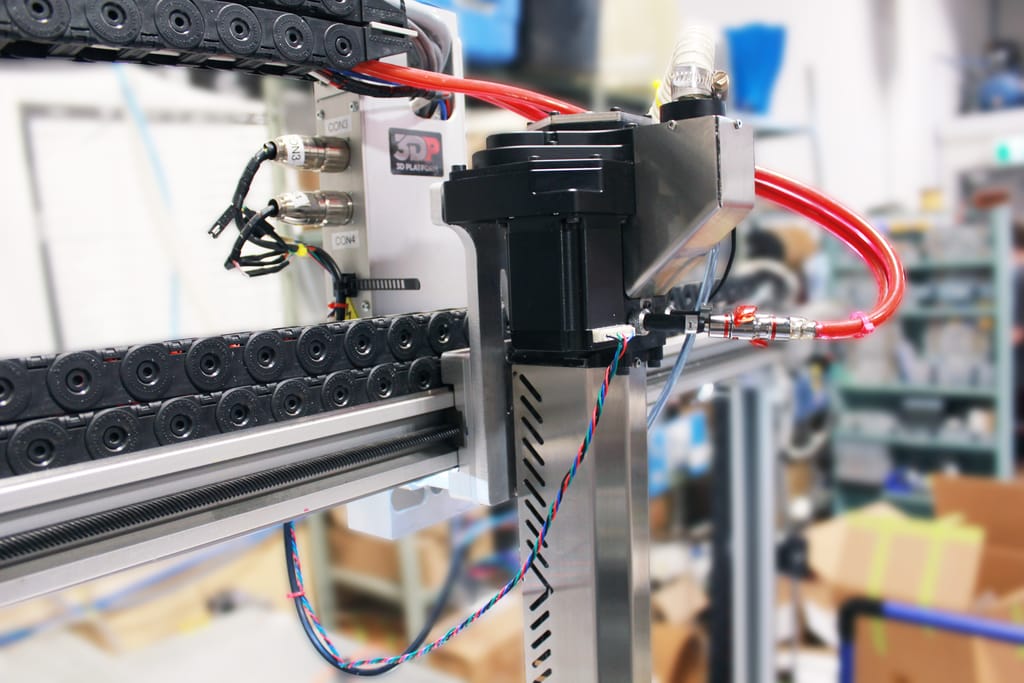

Pulsar™ is compatible with any large-scale 3d printer or even robotic arms and is able to output as much as 500mm³/s (2.5kg/h) of materials.

Starting at CA$11,395

Get a quote

Welcome to the Industrial 3D Printing Era

Ultra High Flow

The Pulsar can output up to 500 mm³/s (2.5kg/h). It is our highest output flow solution and one of the fastest portable pellet extruder on the market.

Customized Extrusion Screw

The customized screw design is optimized for 3D printing with high resolution.

Tri-zone Heating Control

The triple heat zone design ensures the polymer is at a constant temperature. The top section receives cold pellets and generates more heat to melt them. Then, the middle zone stabilizes the polymer at a precise temperature. Finally, the nozzle heater ensures an even flow.

Automatic Feeding System

The Pulsar can come with an optional feeding system which detects the pellets level. Pellets can be delivered from a bulk source.

Multiple Nozzle Size

Pulsar can be used with large nozzles from 1.00mm up to 5.00mm.

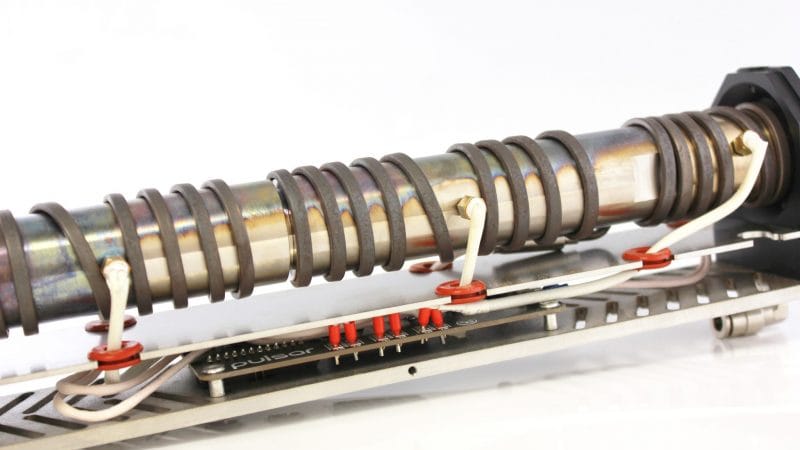

Uniform Heating

The spiral heaters are wrapping the whole heated cylinder and ensure uniform temperature all the way through the end of the extrusion.

Melting Zone Sensor

The temperature sensors are placed 0.50mm from the molten polymer. Readings are reliable and accurate.

Tool Steel Nozzle

The super abrasive resistant steel nozzle avoid any change in nozzle size and height during large prints with abrasive material.

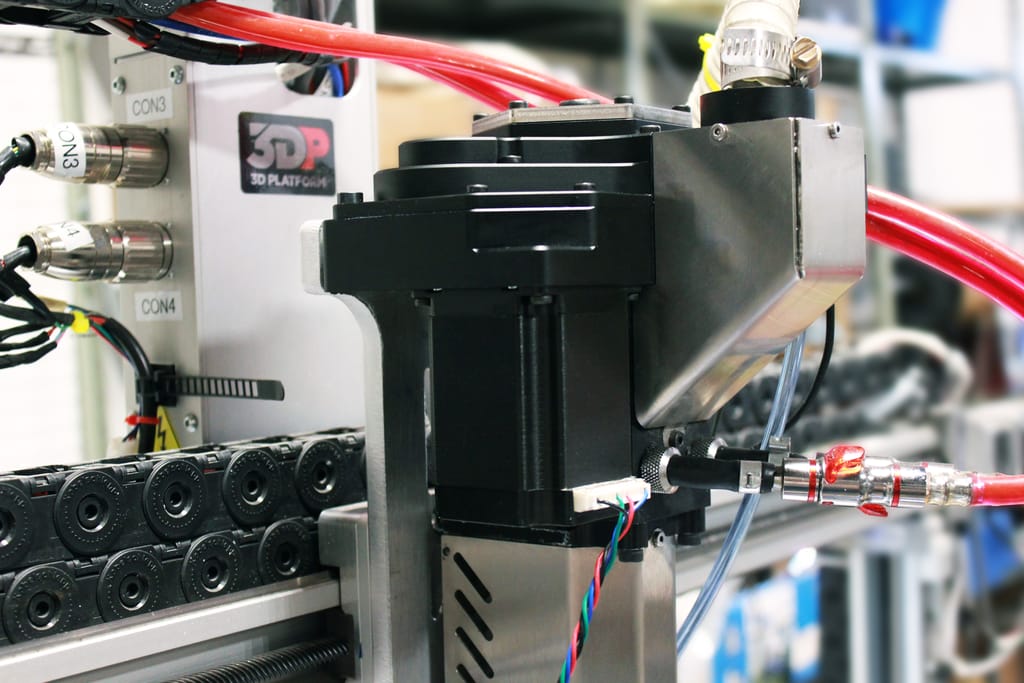

Strong NEMA23 Motor

The Geared NEMA23 motor can handle high flow without a sweat.

Precise Temperature Control

The three PT100 sensors are class A, high precision sensors. The circuit has been designed to use the best resolution between 0°C and 500°C.

Ultra Rugged

The all-metal frame is made from aluminum alloy and is designed to withstand high stresses in tough conditions.

Liquid-cooled

The Pulsar is ready for any environmental conditions. Due to the powerful heating zones, the water-cooling loop ensures the system is at a constant temperature

Anti-Oozing Mechanism

As the screw can’t pull molten plastic, an anti-oozing mechanism ensures nice looking prints without any flaws.

High-Temperature Materials: PEEK, Ultem, PSU

The high-temperature heaters, temperature sensors, and extrusion components enable printing up to 500°C.

1100 Watts Heating Power

High flow means high energy. The 1100 Watts heating system ensures stable temperature in high-speed 3D printing conditions.

Non-Planar 3D Printing

The non-planar heatcore version offers more clearance around the nozzle, making it easier to print nonplanar toolpaths. The non-planar can also be mounted on a robotic arm to increase printing possibilities.

Print any plastics

The Pulsar is able to print every single type of plastic pellets currently manufactured on the market

Technical Information

|

Parameter

|

Value

|

Units

|

|---|---|---|

| Weight | 7000 | g |

| Screw diameter | 19.3 | mm |

| Maximum screw operating speed | 60 | RPM |

| Max temperature | 500 | °C |

| Available nozzle sizes | 1.00 1.50 2.00 3.00 4.00 5.00 |

mm |

| Max flow* |

500 3 |

mm3/s kg/h |

| Total length | 500 | mm |

| Screw length | 348 | mm |

| Heating power | 1100 | W |

*With 3D700 PLA at 200 °C