Powering Reliability and Performance in Industrial 3D Printing

Providing powerful, customizable 3D printing components for seamless production.

From Large-Format Pellet Extruders to High-Flow Hotends, our solutions are engineered for industrial-scale precision and efficiency. Book a call to explore how we can elevate your production.

Trusted By

Dyze Design Pellet Extruders

Pulsar® Large-Scale Pellet Extruder

Pulsar™ is a cutting-edge plastic pellet extruder designed for rapid and cost-effective 3D printing of large parts (1 m³+). It is compatible with any large-scale 3D printer or robotic arms, capable of outputting up to 500 mm³/s (2.5 kg/h).

Pulsar® Atom Precision Pellet Extruder

Pulsar™ Atom is a high accuracy precison small format pellet extruder. With a great compression ratio and excellent stability, it provides a material output of 800 grams per hour and can reach temperatures of 450°C.

Dyze Design High Flow Extruders

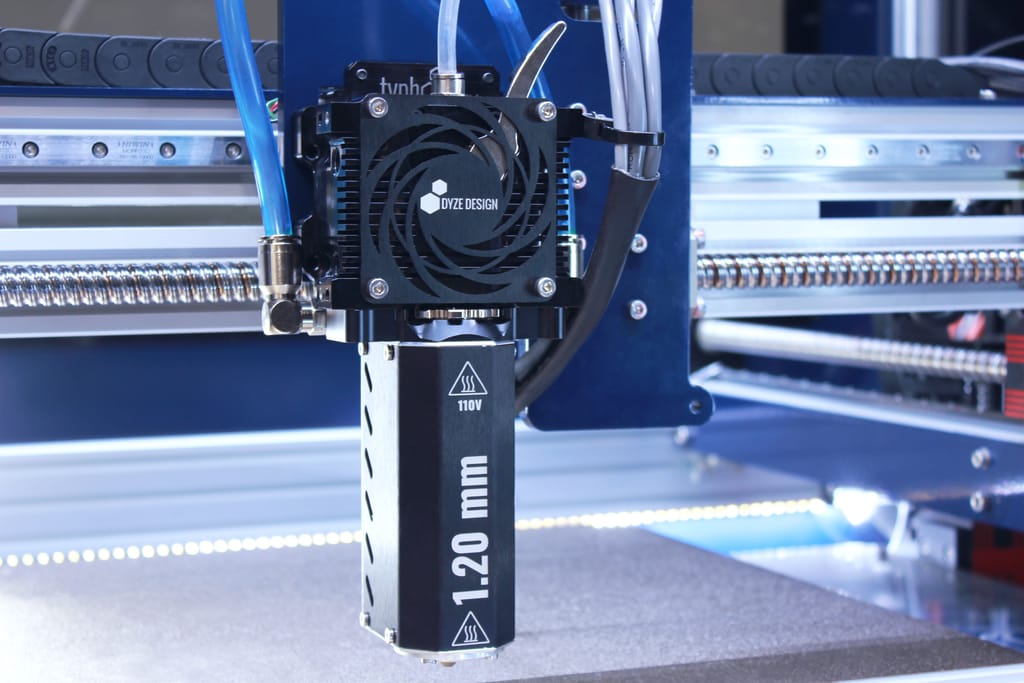

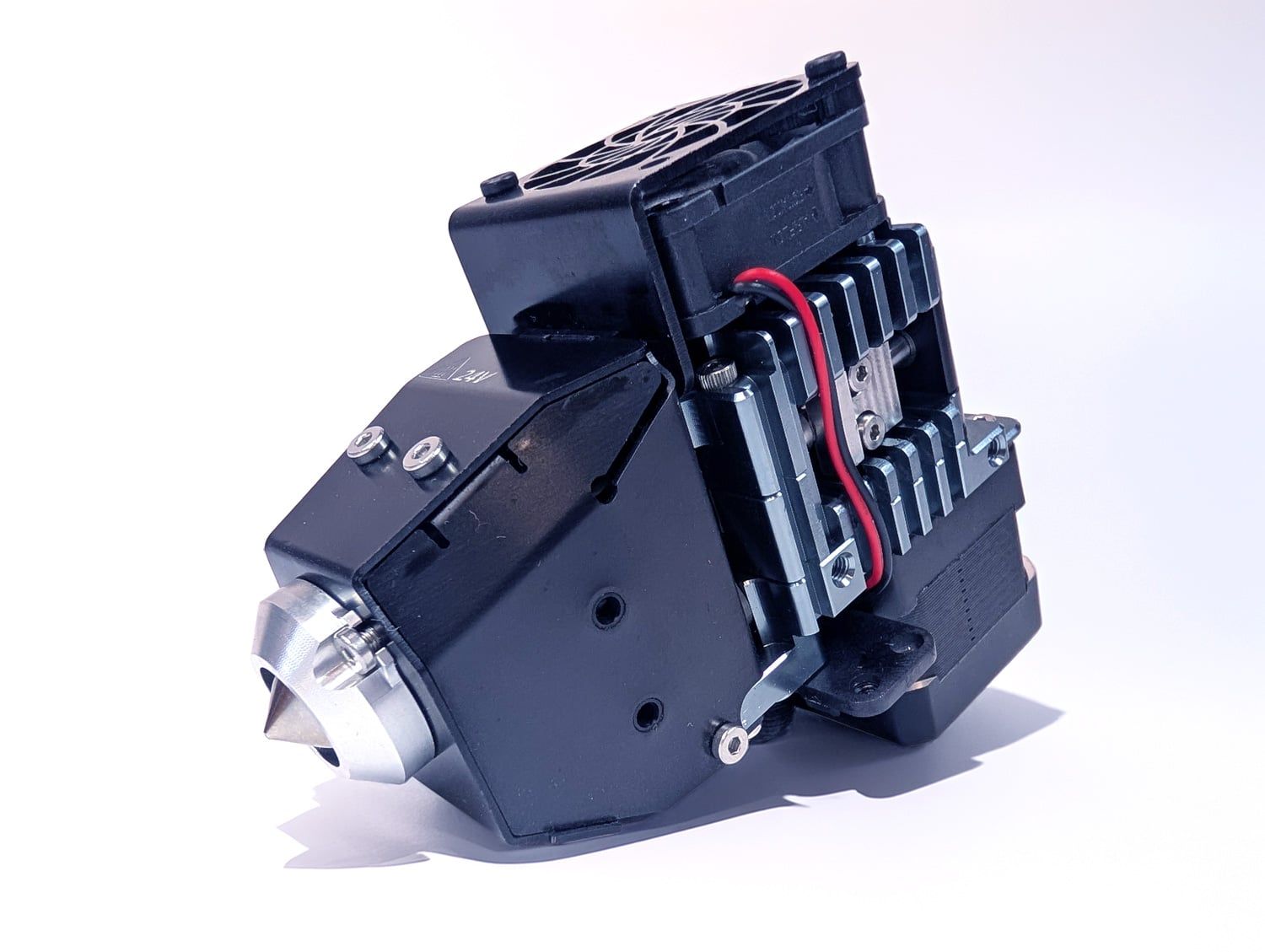

Typhoon® 2.85mm Filament Extruder

Typhoon® is a high flow and fast print all-in-one extruder specifically designed for industrial large-scale 3d printers. This print head is designed to extrude 2.85mm filament, is compatible with standard firmware and is capable of outputting a flow around 200mm³/s (0.9 kg/h).

Zephyr™ 1.75mm Filament Extruder

Zephyr™ extrusion system features one of the highest volumetric flow rates for 1.75mm filament. Boasting the patented MeltCore™ technology, it delivers consistent melting and faster flow rates for enhanced printing efficiency and exceptional performance.

Revolutionizing Industrial Additive Manufacturing

At Dyze Design, we drive the future of high-performance 3D printing solutions for manufacturers worldwide. Our advanced extrusion systems are engineered for precision, scalability, and reliability—empowering businesses to embrace the full potential of additive manufacturing at industrial scales.

Specializing in large-format and high-flow rate printing technologies, we collaborate with industry leaders to create innovative solutions that reduce production time, increase material efficiency, and enable seamless automation. Our extrusion systems are designed to integrate with your manufacturing process, ensuring high throughput and flexibility without compromising on quality.

As a trusted partner in the field of advanced manufacturing, Dyze Design delivers robust and scalable solutions for industries such as medical (O&P), architecture & construction, , design & furniture, automotive, rail, tooling and protective equipments. Our focus is on optimizing production workflows, providing customizable options to meet industrie’s specific needs, and pushing the boundaries of what is possible with 3D printing.

Explore the next level of additive manufacturing with Dyze Design—where innovation, efficiency, and scalability come together to power your production.

Hear from our customers

News

Filament Innovations Aligns with Dyze Design to Revolutionize Additive Manufacturing in the O&P Industry

This strategic partnership aims to enhance precision, speed, and quality in 3D printed prosthetic sockets with Dyze Design’s new advanced industrial motion I/O controller. MONTREAL, QC, September 09, 2024 – Filament Innovations, a leading Pennsylvania-based OEM specializing in additive manufacturing

Flow-To-RPM Factor: Optimize Your 3D Printing with Pellet Extruders

Learn to optimize your 3D printing with pellet extruders. This guide covers key steps for calculating screw speed, determining flow rates, and adjusting RPM for optimal results. Perfect for those transitioning from filament to pellets or enhancing pellet-based print precision.

What is the best Dyze extruder and hotend for your application?

Choosing the right extruder for your 3D printing needs can be a daunting task, especially with the range of options available. In this blog post, we’ll break down the differences between each Dyze Design extrusion systems.

We’ll explore the

Webinar – Increase Your Profitability With High-Flow Material Extrusion 3D Printing

Until recently, 3D printing was primarily used for R&D and prototyping purposes. Nowadays, additive manufacturing is proving to be a real manufacturing solution. Industries are using it for small and large series functional mechanical parts or consumer goods. While one