Typhoon® LCX & Typhoon®

Air High-Flow Extruders

Higher Flow Rate. Faster Printing.

Typhoon® is described as high flow and fast print all-in-one extruder 3D printing head specifically designed for industrial large-scale 3d printers. This print head is designed to extrude 2.85mm filament, is compatible with standard firmware and is capable of outputting a flow around 200mm³/s (0.9 kg/h). This means quicker print at a high deposit rate.

*Starting at CA$3530

Get a quote

Super High Flow

The Typhoon™ extruder can output 200 mm³/s (0.9kg/h), one of the highest flow rate for 2.85mm filament.

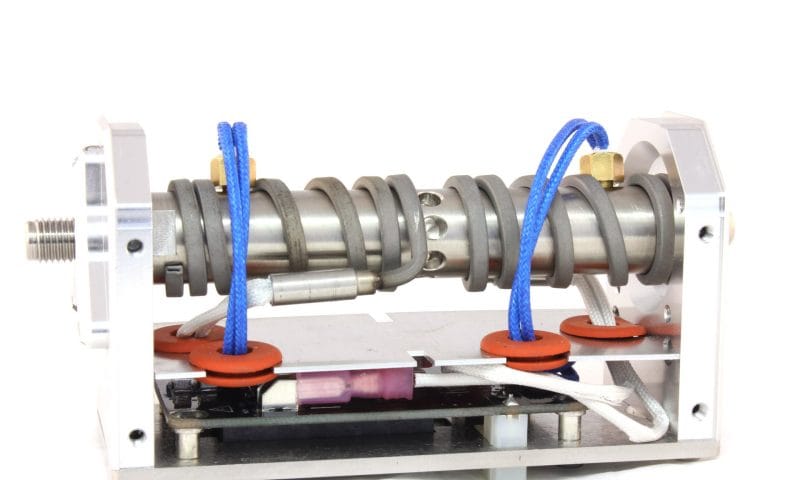

Quad Pinch System

The quad pinch system is a four-point contact with the filament. This extreme grip ensures no slipping ever occurs. Any type filament can go through this mechanism, even very soft and flexibles ones.

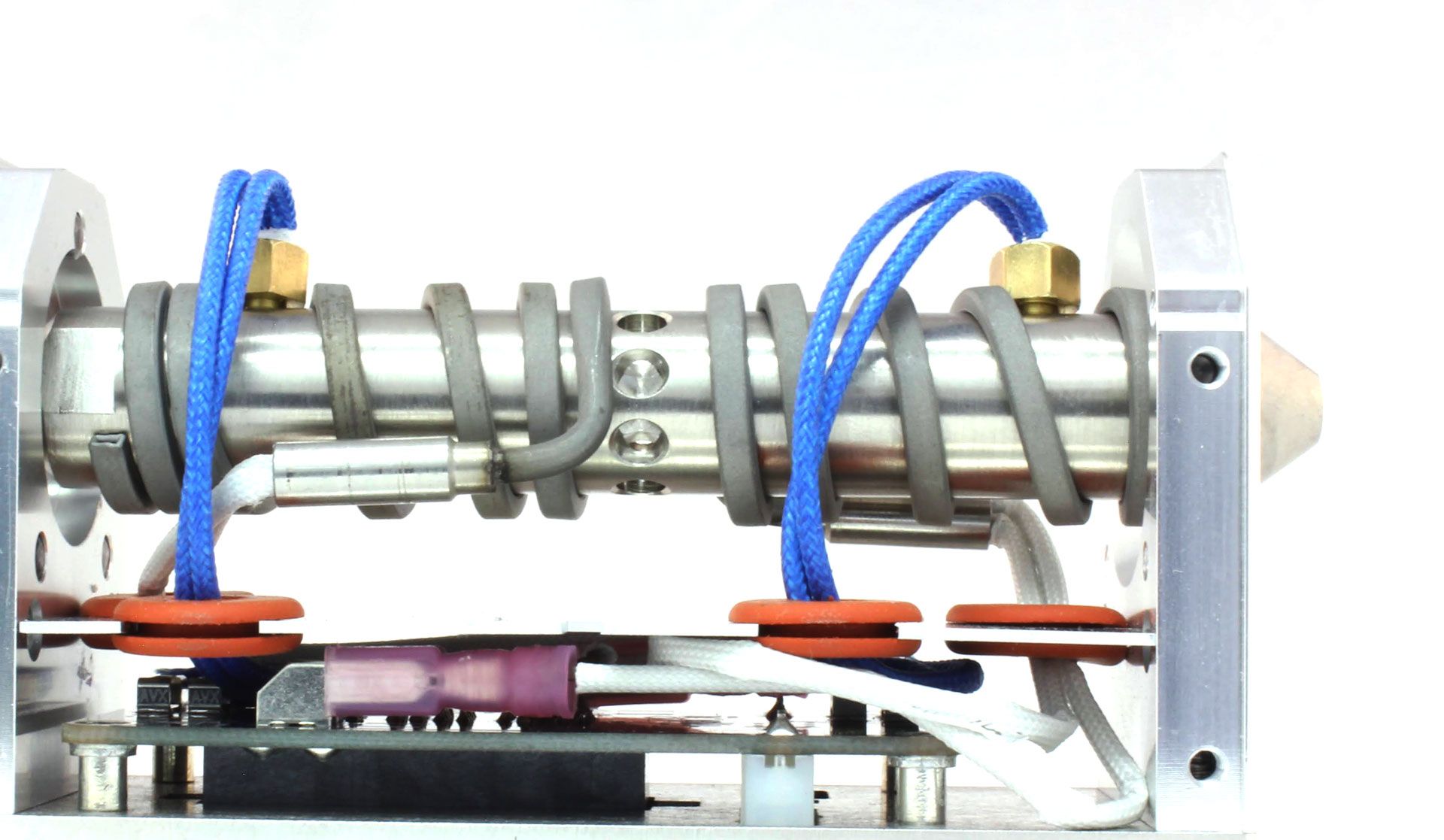

Dual Heating Zone

The dual heat zone design ensures the polymer is at a constant temperature. The top section receives cold filament and generates more heat to melt the polymer. Then, the bottom zone ensures that the polymer is at a precise temperature to output an even flow.

Non-Planar 3D Printing

Precise Temperature Control

The two PT100 sensors are class A, high precision sensors. The circuit has been designed to use the best resolution between 0°C and 500°C.

Super Strong Heat Transition Tube

The new transition tube design takes the full advantage of titanium low thermal conductivity plus the rigidity of a large tube. The machining is highly complex and done by a specialized manufacturer.

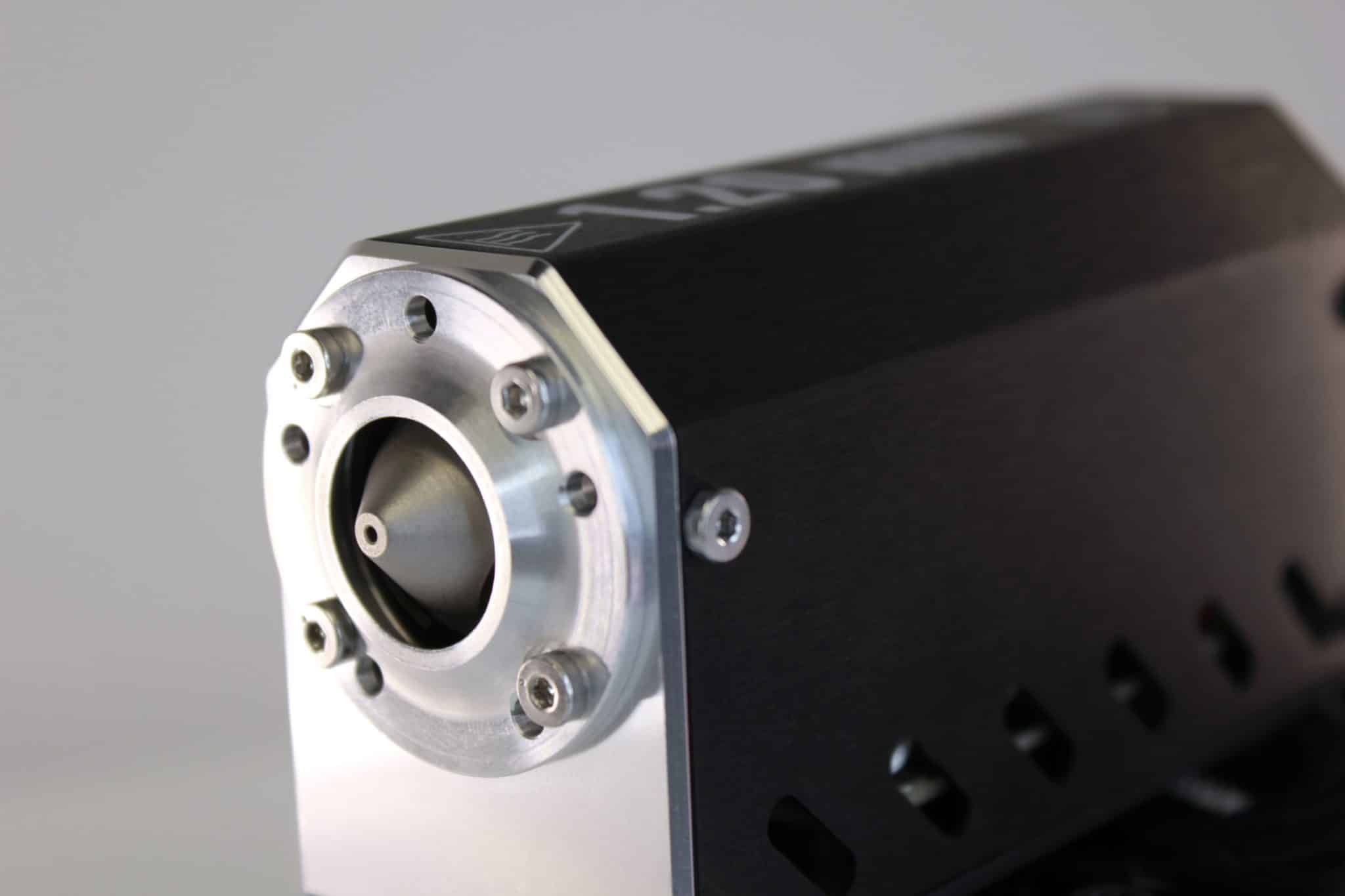

Quick Heatcore Change

Each heatcore can be switched easily with a few knob turns. The taper assembly ensures solid contact with the housing.

Easy Filament Swap

The top lever moves all driving mechanisms away from the filament, allowing filament switching in just a second.

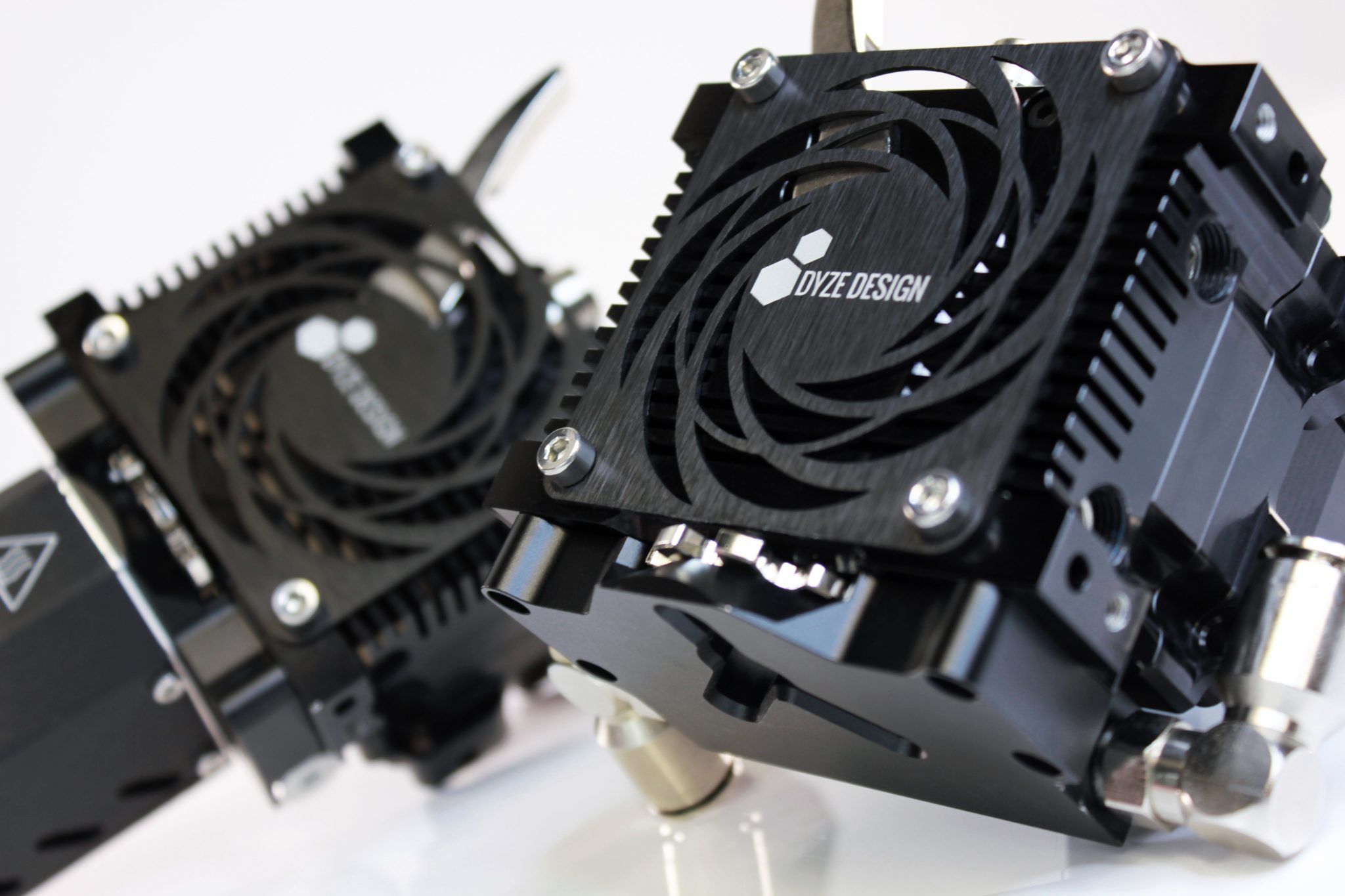

Strong NEMA23 Motor

The NEMA23 motor can handle high flow without a sweat. The driving system is able to push as much as 20 kg.

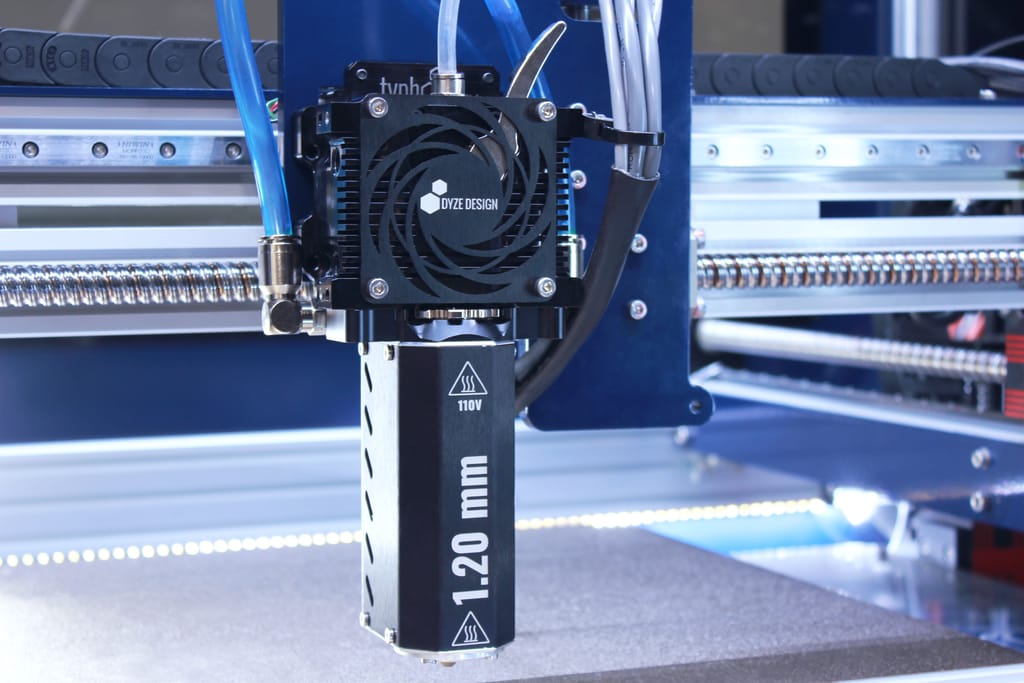

Air-Cooled or Liquid-Cooled

The Typhoon® comes in 2 versions: the Typhoon Air keeping the cold zone at the right temperature using a fan; or the Typhoon LCX, ready for any environmental conditions thanks to its water-cooling loop ensuring the system is at a constant temperature in heated chambers.

Tool Steel Nozzle

The super abrasive resistant steel nozzle avoid any change in nozzle size and height during large prints with abrasive filaments.

Ultra Rugged

The all-metal frame is made from aluminum alloy and is designed to withstand high stresses in tough conditions.

4.6: 1 Metal Gears

The gears are made from alloys steel and are heat treated for long useful life. Each gear is mounted on strong ball bearings, reducing friction losses and smoothing operation.

Print any plastics

The Typhoon™ extruder is able to print every single type of 2.85mm plastic filaments currently sold on the market

Technical Information

|

Parameter

|

Value

|

Units

|

|---|---|---|

| Weight | 1750 | g |

| Filament size | 2.85 | mm |

| Maximum output flow* | 200 | mm3/s |

| Max printing temperature | 450 | °C |

| Max environment temperature | 100 | °C |

| Available heatcore sizes | 0.60 0.90 1.20 1.80 2.50 |

mm |

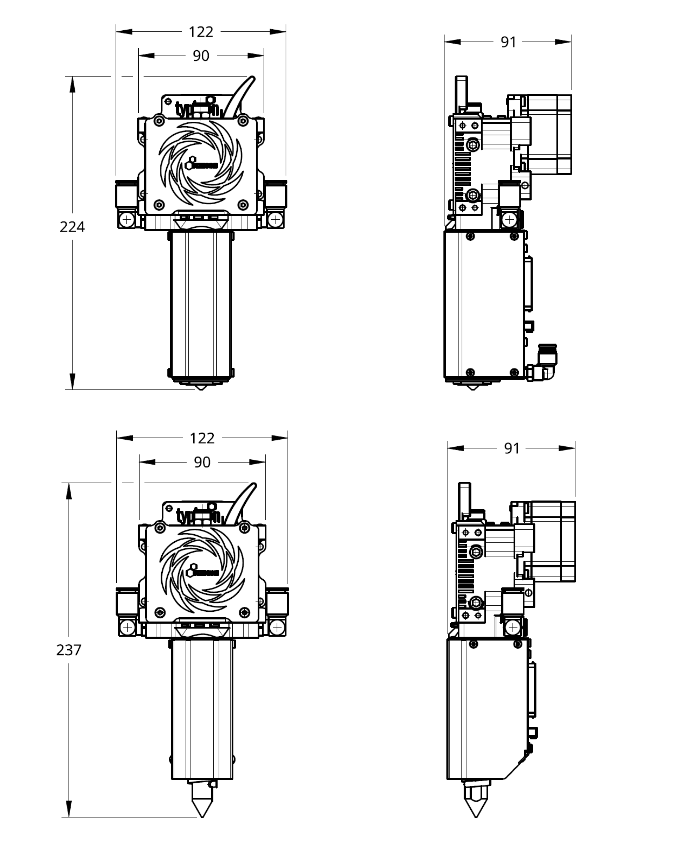

| Total height | 224 / 237 | mm |

| Heating power | 400 | W |

*Variable depending on the type of filament see documentation