- Pellet Extruders

- High-Flow Extruders

- Other Extruders & Hotends

- Online Store

- Support

-

-

Need more help ?

If you’re having technical issues with one of your Dyze Design product and can’t find what you’re looking for in our installation and guides section, open a ticket and our support team will help you.

-

- Blog

-

Recent Posts

Flow-To-RPM Factor: Optimize Your 3D Printing with Pellet Extruders

What is the best Dyze extruder and hotend for your application?

Webinar – Increase Your Profitability With High-Flow Material Extrusion 3D Printing

The Adverse Effects of PTFE Restrictions

How the Pulsar™ pellet extruder improved art & architectural design fabrication

-

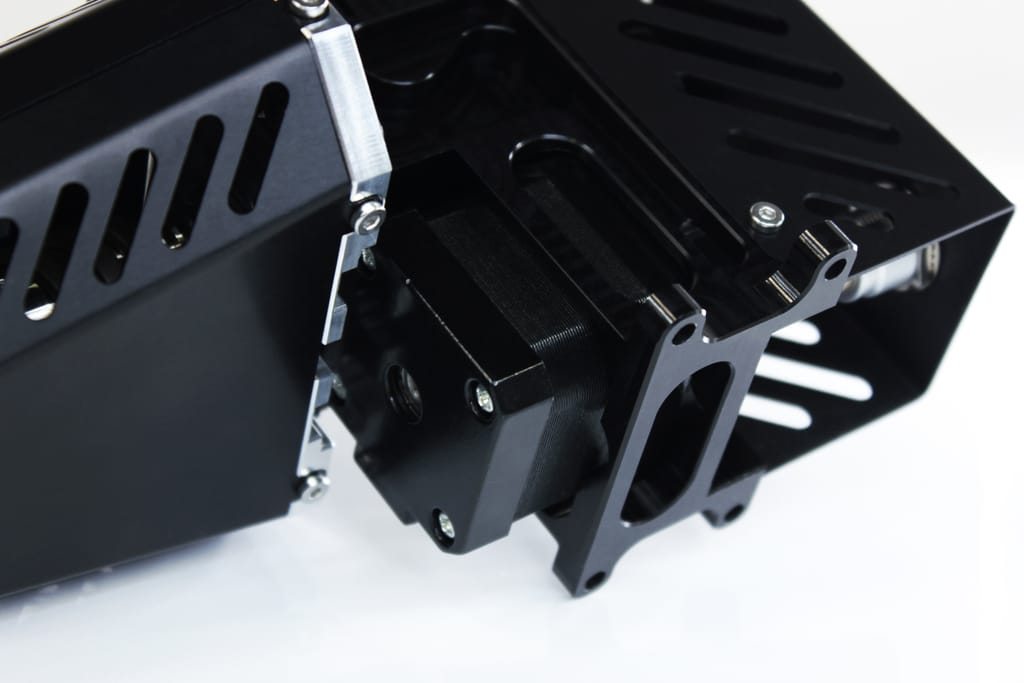

Pulsar™ Atom Precision Pellet Extruder

Unlock Precision. Elevate Productivity.

Pulsar™ Atom goes beyond being a pellet extruder; it’s an exquisite piece of precision engineering developed to increase production in 3D printing. With compression ratio optimized for 3D printing and exceptional stability, it transcends the constraints of thermoplastic materials by reaching high temperatures of up to 450°C.

Your key to attaining accuracy, speed, and exceptional performance in 3D printing is Pulsar™ Atom. With a material output of 800 grams per hour, find out how Pulsar™ Atom will change your operations one layer at a time.

Secure Your Pulsar™ Atom Now

Don't miss the opportunity to revolutionize your 3D printing. Secure your Pulsar™ Atom today. Simply fill out the form below to request a quotation and be ready to experience precision in pellets 3d printing like never before.

Starting at CA$5,000

Precision Meets Performance

Pulsar™ Atom is engineered to reach temperatures up to 450°C, opening up a world of high-temperature materials.

No more limitations. No more compromises. Just precision.

Reliability Matters

Say Goodbye to Extrusion Challenges

Pulsar™ Atom makes 3D printing better by using consistent extrusion technology. This means the material is evenly fed and the printing process is dependable. You get good quality prints without needing to fix problems or reprint. Pulsar™ Atom saves time and makes 3D printing easier.

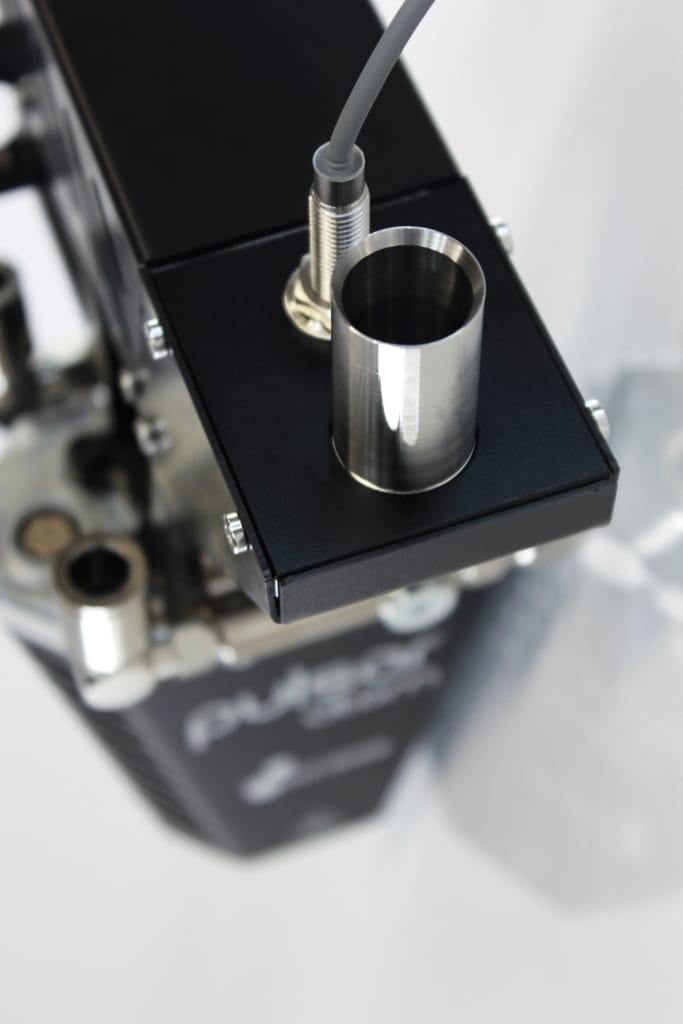

Exceptional Heat Resistance

With a tolerance for temperatures of up to 150°C, Pulsar™ Atom is built to handle the heat in your environment, ensuring durability and reliability.

Minimal Compression Ratio

Achieving a minimal compression ratio of 1.5, Pulsar™ Atom ensures consistent and reliable extrusion across a wide range of thermoplastics.

Impressive Output Flow

You can count on Pulsar™ Atom to deliver an output flow of approximately 0.8kg per hour, enhancing your production capabilities.

Precise Mass Flow Stability

With a mass flow stability of less than 5%, Pulsar™ Atom ensures precision in every print.

Adapt with Ease

Enhance Your Workflow

Struggling with adaptability? Pulsar™ Atom offers over 45 degrees of nozzle maneuverability and an auto material feeding add-on. Whether you’re printing or using robotic arms, it adapts effortlessly to your workflow.

Exceptional Maneuverability

With over 45 degrees of liberty around the nozzle, Pulsar™ Atom is perfect for robotic applications and non-planar printing.

Versatile Nozzle Options

Pulsar™ Atom offers nozzle sizes ranging from 0.4mm to 2.5mm, providing flexibility for various printing needs.

Liquid-Cooling Add-On

For high-temperature environments, our liquid-cooling add-on ensures optimal performance and longevity.

Auto Material Feeding

Take advantage of the optional auto material feeding add-on for seamless printing experiences.

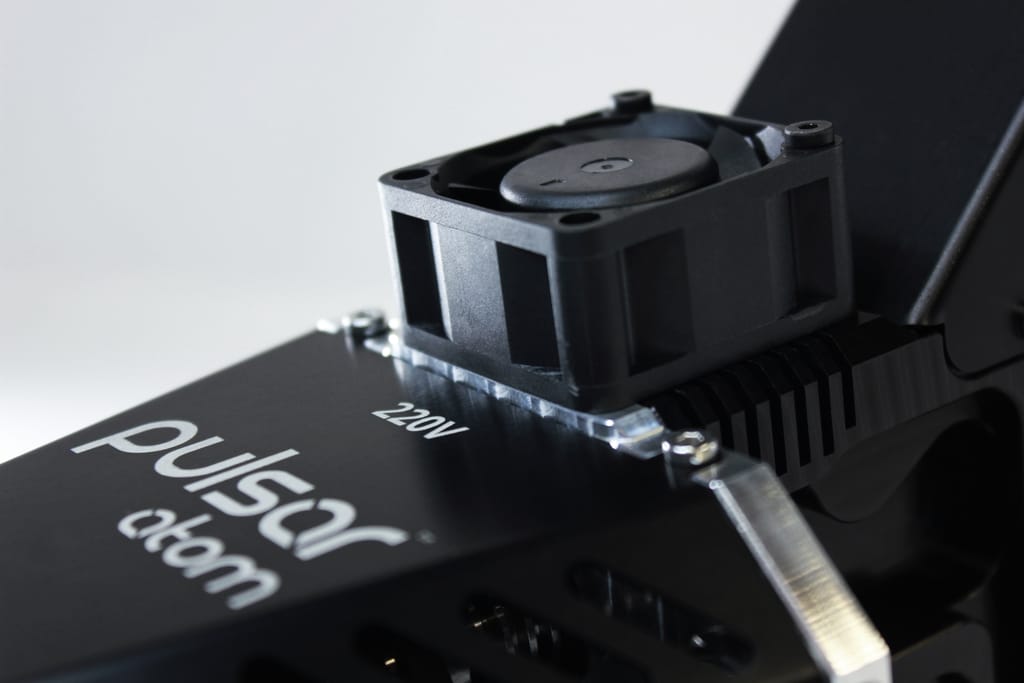

Experience Precision Without Compromise

Size doesn’t matter; precision does. Pulsar™ Atom’s compact design delivers precision that defies expectations. It’s lightweight, fits seamlessly into your setup, and is universally compatible.

- Less than 1.5kg in weight and under 245mm in height

- Available in 110V or 220V

- Integrates with open-source firmware and popular 3D printer controller boards

- Perfect for Robotic Arms

Technical Information

| Parameter | Specification |

|---|---|

| Weight | Less than 1.5kg |

| Height | Less than 245mm |

| Flow Rate (Output Flow) | 800g per hour* |

| Nozzle Sizes | 0.4mm, 0.6mm, 0.9mm, 1.2mm, 1.8mm, 2.5mm |

| Voltage | 110V or 220V |

| Max Environment Temperature | Up to 150°C |

| Max Operating Temperature | Up to 450°C |

| Compatible Pellets | Shorter than 4mm** |

*Output flow data represents the latest achieved results from testing the alpha version. Please note that the actual output flow of the current release version may vary slightly

**Optimal performance is achieved with pellets that are 4mm or shorter, measured as the maximum (longest) straight-line distance from one end to the other.