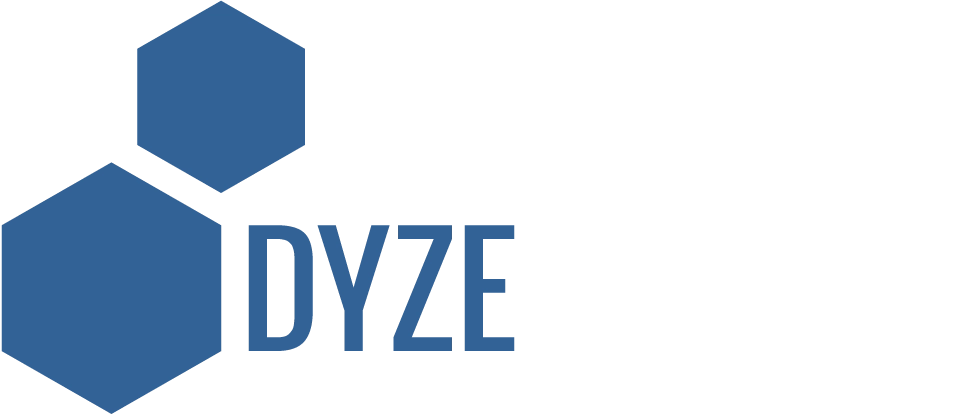

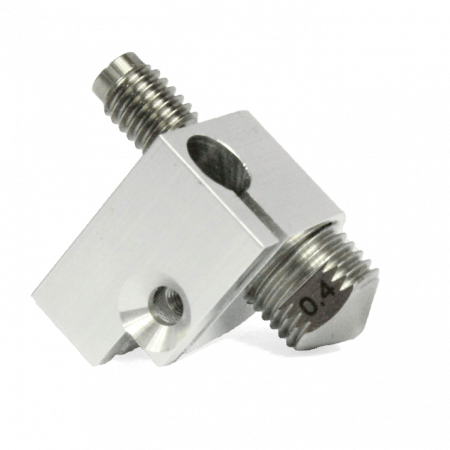

DyzEnd-X Hotend

Print. Anything.

With a 3d printer hotend like DyzEnd-X, you can literally print any type of material. It's all metal conception, high-temperature sensors, small form factor and jam-free technology makes it one of the best high-performance and top quality hotend you'll ever need. And it's faster than ever.

Starting at CA$116

Designed for advanced printing

Fast Print

The aluminum melt block transfer heat very quickly to the nozzle for an efficient and very fast printing speed. Furthermore, the long melt zone can handle very high filament feed without any trouble.

Fast Heating

The DyzEnd-X can heat very quickly. Hence, in only 70 seconds, it reaches 210°C.

High Temperature

The high temperature sensor used inside the DyzEnd-X enable precise readings up to 500°C. As a result, you can use any thermoplastics with the DyzEnd-X.

All Metal Melt Zone

The heated zone is made entirely from metals which can withstand very high temperature before losing mechanical properties. Even the sensors and heaters are protected by high temperature resistant sleeves.

Cold Swappable Nozzles

By using a very special high-temperature sealing washer, the DyzEnd-X is able to switch nozzles at room temperature. No leaks, no burning hazard.

Small Form Factor

By using a low conductivity transition tube, the DyzEnd-X is designed very small. This enables you to use your build volume more efficiently.

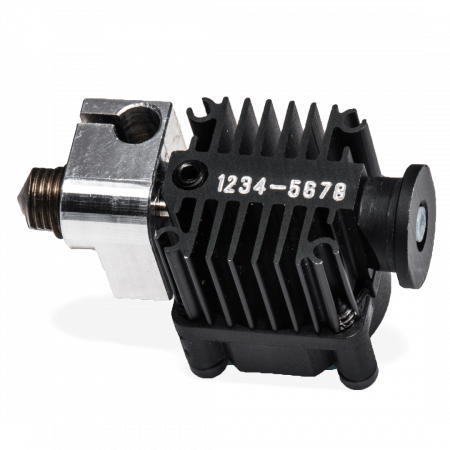

Titanium Transition Tube

The DyzEnd-X is made from a titanium alloy meticulously chosen to provide both stiffness and low thermal conductivity, limiting heat losses to the cold side.

Wear resistant nozzle

The DyzEnd-X comes built in with high wear resistant nozzle.

We’ve personally measured and tested the performance.

Liquid Cooling Ready

The DyzEnd-X can be easily converted to a liquid cooled setup with Dyze Design’s specialized cooling blocks

Bowden Ready

The DyzEnd-X is compatible with a M8x1.25 push to connect fitting. The 4mm PTFE tube can be inserted through the connector and guides the filament as far as possible inside the hotend.

Groove Mount

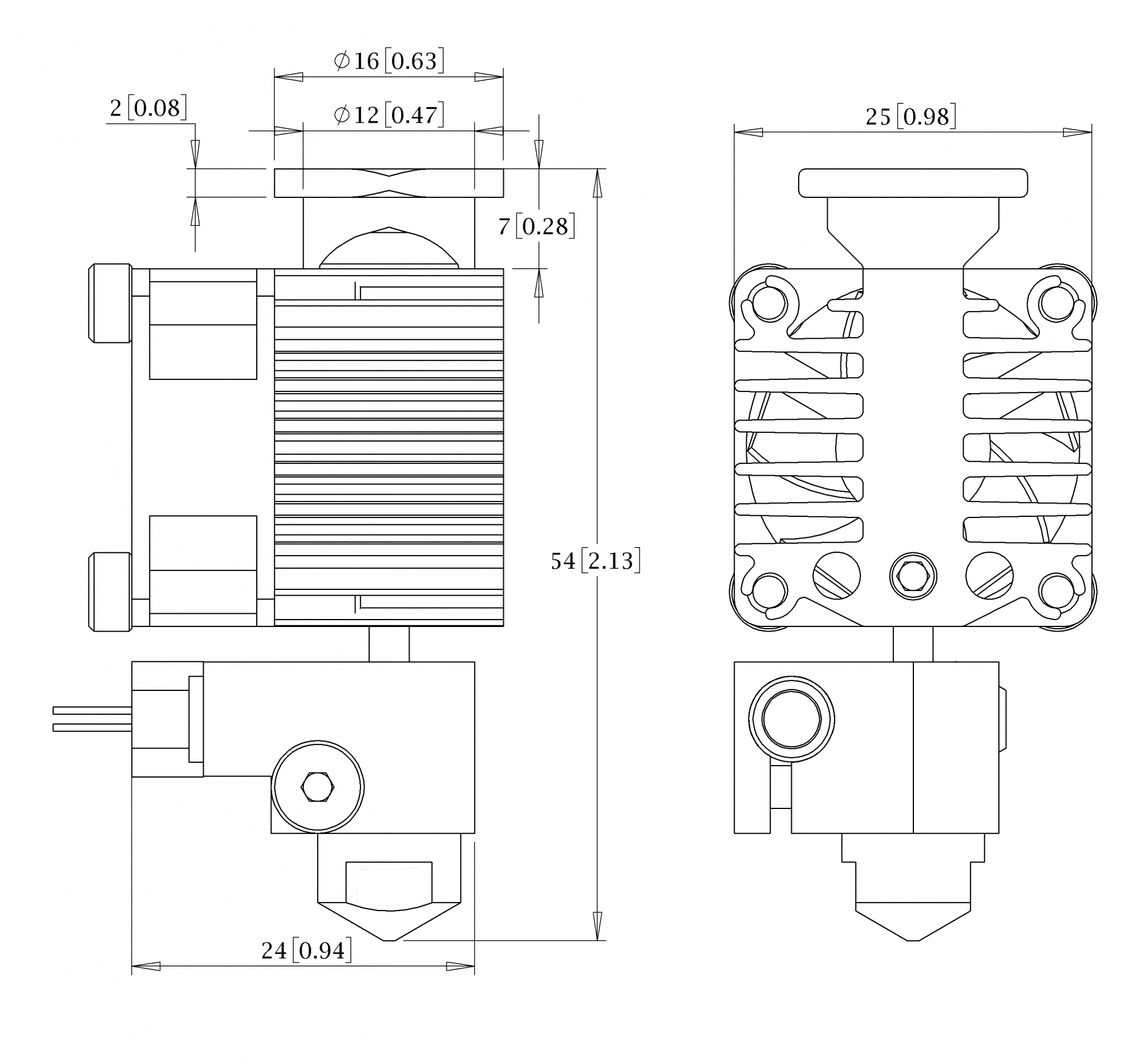

The hotend mounting mechanism is based on the form factor called “Groove Mount”. The 12mm groove makes it very easy to switch and maintain your hotend and nozzle.

Rigorous Quality Control

Critical parts are under strict quality control upon reception and are 100% tested.

Our qualified assembling team has many tools for validating performance throughout the assembly process.

Typical Performance Characteristics

DyzEnd-X actual flow (mm³/s) versus expected flow (mm³/s)

Relative output (Expected output / Actual output ) versus Flow (mm³/s)

Print any plastics

The DyzEnd-X is able to print every single type of plastic filaments currently sold on the market

Technical Information

|

Parameter

|

Value

|

Units

|

| Weight – Hotend | 52 | g |

| Operating Voltage | 12, 24 | V |

| Operating temperature (air cooled) | 0 to +60 | °C |

| Operating temperature (liquid cooled) | 0 to +120 | °C |

| Top thread | M8x1.25 | mm |

| Thermistor resistance at 25°C (500°C) | 4700 | kΩ |

| Thermistor resistance at 200°C (500°C) | 8 | kΩ |

| Maximum temperature – 40W | 420 | °C |

| Maximum temperature – 60W | 500 | °C |