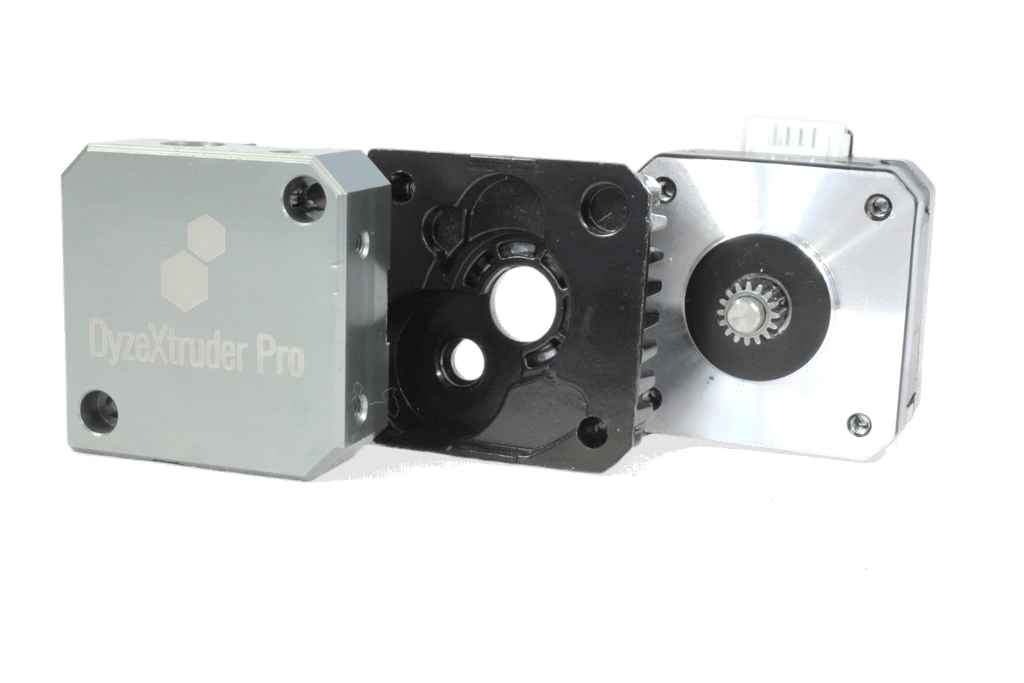

DyzeXtruder Pro

Extrusion better than ever

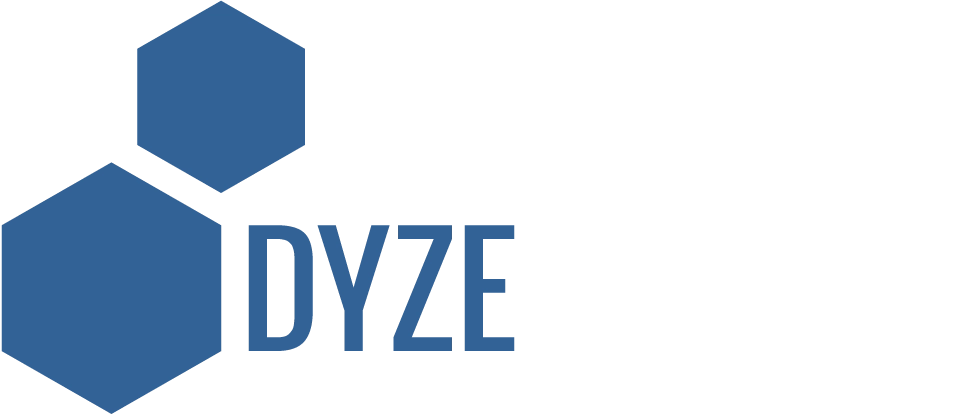

DyzeXtruder Pro is a very lightweight all-metal extruder and also one of the smallest on the market. It is not larger than the NEMA 17 it uses, making it very space efficient on a multiple extruder configurations. Besides, the extruder is stronger than ever. With the improved teeth and new bearings types, the DyzeXtruder Pro is able to push as much as 10 kg (22 pounds) of force. This is more than necessary for all 3D printing applications. Finally, the new backblock has cooling fins for increased heat spreading in room environments.

Only CA$275

Designed for professional printing

Stronger

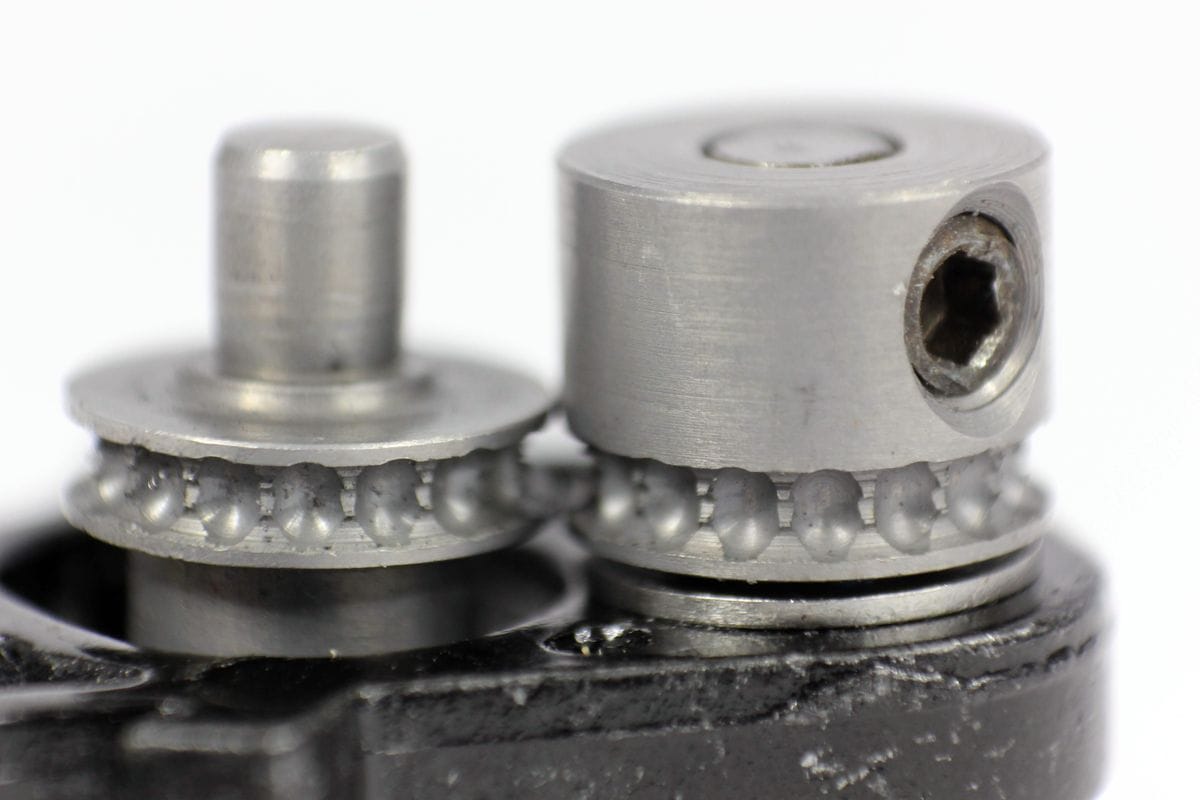

With the improved teeth and new bearings types, the DyzeXtruder Pro is able to push as much as 10 kg (22 pounds) of force. This is more than necessary for all 3D printing applications.

Toolless HotEnd Removal

Take your hotend off your extruder in just a few seconds with the thumb screw. This will loosen the groove mount and free your hotend.

Multiple Mounting Possibilities

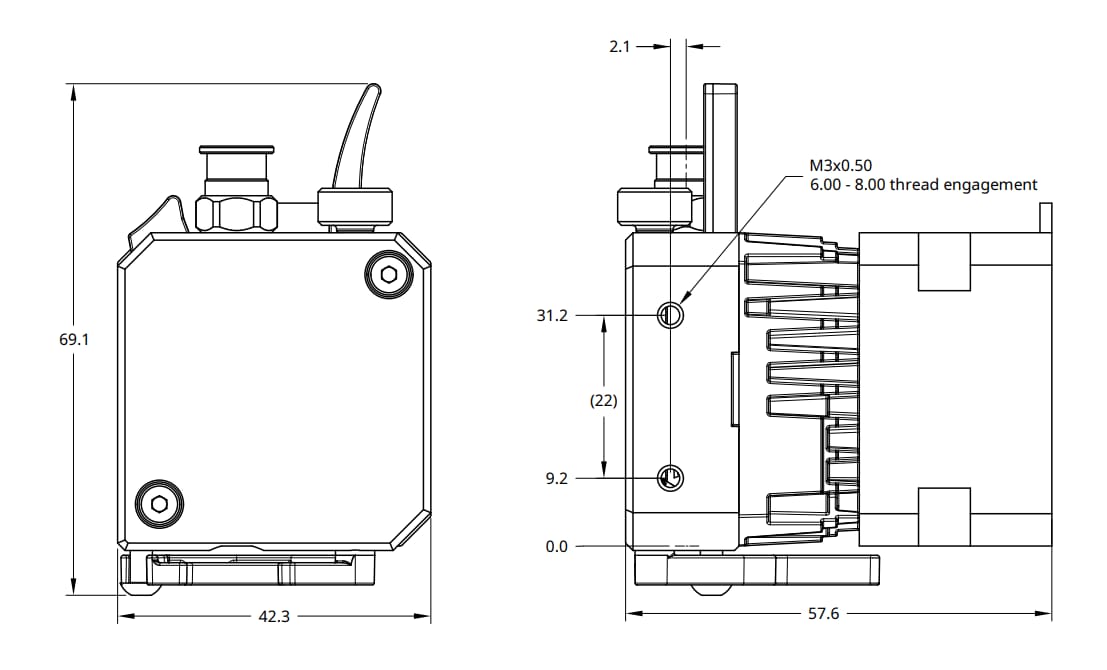

The side mounting threads make it very easy to assemble; two M3 screws are included to fit the DyzeXtruder Pro on a printer, bracketless. You can also mount the extruder on a panel.

Cooling Fins

The new backblock has cooling fins for increased heat spreading in room environment. The fins are thick enough to offer the same thermal conductivity performance as the GT block in watercooled environment.

Guided Filament

The guides conduct the filament out of the extruder. They follow the teeth shape, allowing no other exits for the filament. The whole part has a low friction coating, increasing the pushing efficiency.

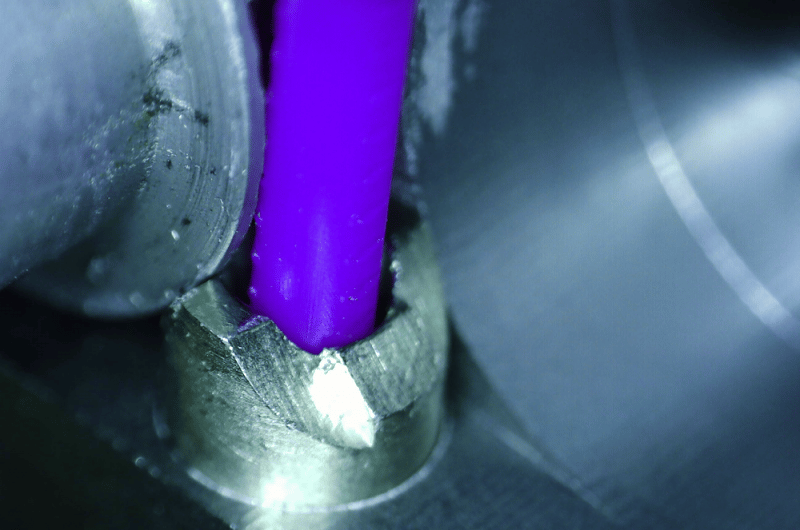

Completely Redesigned Teeth

35% more pushing force with rigid filaments

25% more pushing for with flexible filaments

Keep the filament round, even after 100+ passages

Dual pinch drive system

The dual-pinch system allows a higher pushing force with a lower filament pressure. It reduces the risk of flattening the filament when highly detailed prints require a lot of retractions.

All metal

The aluminum housing is designed to offer a reliable operation, even in a high temperature environment when combined with a liquid cooling system.

Lightweight

The gear ratio was chosen to get the best of a very small motor.The DyzeXtruder Pro is a lot lighter than a traditional extruder with a planetary gearbox, allowing for faster printer accelerations.

Small form factor

The DyzeXtruder Pro is not larger than the NEMA 17 it uses, making it very space efficient on a multiple extruders configuration and one of the smallest on the market. Saving space on a carriage can allow you to print larger parts on a single printer.

Connectors

The DyzeXtruder Pro comes with a connector and a cable for its motor so you can easily maintain it.

Metal Reduction Gears

The DyzeXtruder Pro has a 5.65 : 1 gear ratio. This ratio has been chosen to use the full potential of a very small motor while, enabling very high pushing forces. The gears are custom made from high strength hardened steel. This combination allows low friction operations and a longer life. The gears and bearings are designed to last for hundreds of kilograms in extreme conditions.

Constant pressure

The custom spring has been redesigned to provide the optimal pressure at the filament with the new teeth. You’ll always get the same output flow, reducing the variations involved in changing filaments.

Matched included motor

The included motor is chosen to match the maximum torque tolerated by filaments. The motor won’t grind your filament and will prevent any damage inside the extruder.

Bowden Ready

The DyzeXtruder Pro always comes with a special push to connect fitting. A PTFE tube can be inserted through the connector to guide the filament as far as possible inside the mechanism. A single modification in the firmware can easily transform a direct drive setup into a bowden.

Hotend Positioning

A small pocket under the extruder makes it even easier to locate the hotend.

Print any plastics

The DyzeXtruder Pro is able to print every single type of plastic filaments currently sold on the market

Technical Information

| Parameter | Value |

| Weight | 300g |

| Filament diameter | 1.75mm |

| Operating current | 0.9A |

| Operating temperature | Up to 30°C |

| Operating temperature (liquid cooled) | Up to 120°C |

| Top fitting tube OD | 4.00mm |

| Gear ratio | 5.65 : 1 |

| Groove mount head thickness | 2 – 5mm |

| Mounting screw thread | M3 |

| Mounting screw min thread depth | 5mm |