Tungsten carbide nozzle

CA$79.00

3D printer nozzle in tungsten carbide for the ultimate balance between wear resistance and high performance.

| Title | Range | Discount |

|---|---|---|

| 3 Nozzles 10% off | 3 + | 10% CA$71.10 |

Tungsten Carbide: High flow with abrasion resistance

Tungsten carbide, not to be confounded with tungsten alloy, which is metal, is the ceramic of choice when it comes to wear and abrasion resistance. Cutting tools for steel and tool steel are made from tungsten carbide. It is also used extensively in the mining industry as a button insert for crushing rocks.

The high thermal performance of the tungsten carbide keeps the nozzle tip hot, thus allowing faster printing speed without sacrificing the quality.

Tungsten carbide has exceptional wear resistance due to its high hardness. Both the nozzle hole size and height will always stay the same, no matter how long or how hard you use it.

Compared to a reference brass nozzle, the tungsten carbide nozzle is much easier to extrude. In fact, the output flow can be increased by around 80% while having the same results.

For more information: https://dyzedesign.com/tungsten-carbide-nozzle/

Ultra wear resistant

The high hardness of tungsten carbide will provide a carefree extrusion experience. Its unparalleled wear resistance will ensure that both the nozzle diameter and flat will keep the same dimension, and so will your printed parts.

Low pushing force

The high thermal conductivity of both the nozzle tip and body will pump all the required heat to maintain an even temperature while extruding. Viscosity highly depends on the plastic temperature for a constant shear rate. The flow pressure will be constant resulting in excellent results and stability. The ease of pushing the filament will give an extra margin for your extruder safety.

Faster speed

Due to the high thermal performance of the nozzle in general, the printing speed can be pushed even further without sacrificing the quality. The special shape inside the nozzle allowed by the manufacturing technique improves the flow where the diameter gets reduced, thus allowing a faster flow rate.

Low friction

The whole nozzle is electroless nickel plated for enhanced slippery properties. Plastic will slide on the nozzle instead of sticking to it. This result is cleaner parts and less dragging problems.

Any material

From printing PLA to carbon fiber reinforced plastics, this nozzle can handle anything. The low friction coating greatly helps with flexible filaments allowing, them to slide through the nozzle. A single nozzle will offer quality prints, wear resistance, and high flow, so there is no need to get a ton of different nozzles when a single one can offer the best of all worlds.

Unbeatable price/performance

Tungsten carbide is easier to produce than corundum (Sapphire, Ruby, etc) and the performance is very similar for abrasion and much more performant for thermal conductivity. The use of steel makes it very easy to manufacture and offers amazing thermal performance. The whole package is a win-win situation in terms of performance and price.

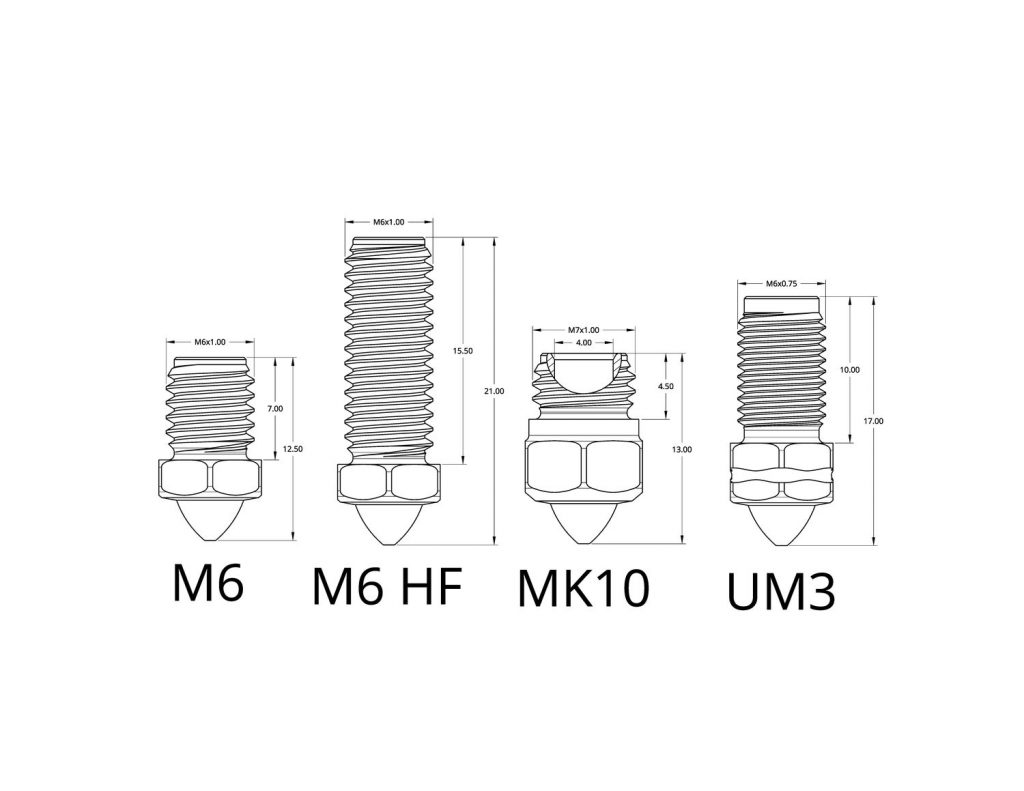

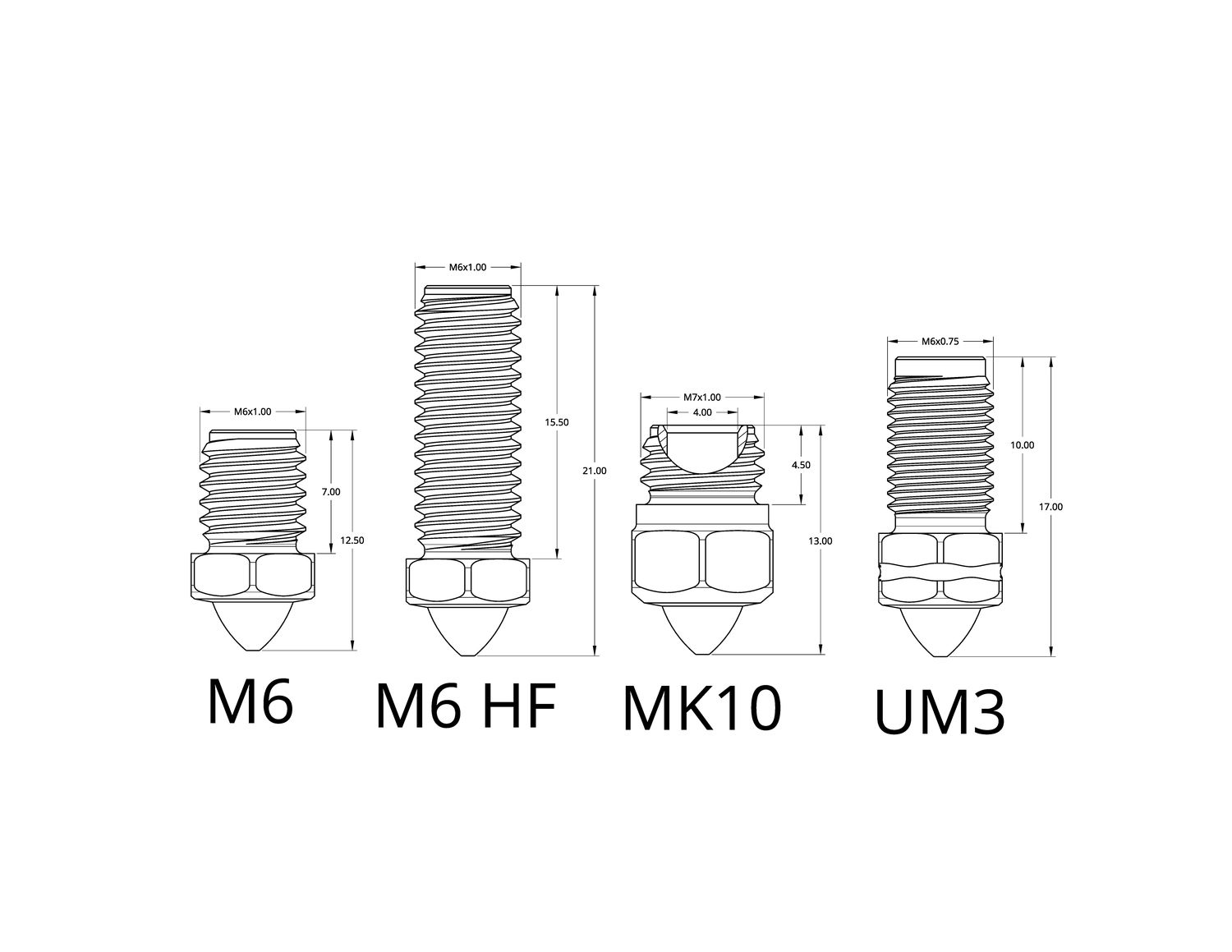

| T (°C) | Maximum torque (Nm) | |||||

| M6-1.75mm | M6-3.00mm | M6-3.00mm HF | M7 MK10 | M10 | UM3 | |

| 25 | 1.9 | 1.7 | 1.7 | 2.7 | 10.1 | 1.9 |

| 200 | 1.6 | 1.4 | 1.4 | 2.2 | 8.2 | 1.5 |

| 300 | 1.3 | 1.2 | 1.2 | 1.9 | 7.1 | 1.3 |

| 400 | 1.1 | 1.0 | 1.0 | 1.6 | 5.9 | 1.1 |

| General specifications | |

|---|---|

| Housing material | High thermal conductivity steel |

| Tip material | Tungsten carbide, Fine Grade |

| Is electrical conductive | Yes |

| Maximum working temperature | 500 °C |

| Maximum working pressure | 25 MPa |

|

3D Printer |

|||

| Tungsten Carbide UM3 | Tungsten Carbide M7 MK10 | Tungsten Carbide M6 1.75mm | Tungsten Carbide M6 High Flow 3.00mm |

| Ultimaker 3 | FlashForge Creator Pro | Raise3D N1 | 3D Platform |

| FlashForge Creator X | Raise 3D N2 | LulzBot Taz 5 MoarStruder | |

| FlashForge Dreamer | Raise 3D N2 Plus | LulzBot Taz 6 MoarStruder | |

| FlashForge Finder | Prusa i3 MK2 | ||

| Qidi Tech X-One | Prusa i3 MK3 | ||

| Qidi Tech I | E3D BigBox | ||

| PowerSpec 3D X | gCreate gMax 15XT+ | ||

| Wanhao i3 V2.1 | Makerbot Replicator 2 | ||

| Wanhao i3 Plus | Makerbot Replicator 2X | ||

| Wanhao Duplicator 6 | Felix Pro 2 | ||

| Wanhao Duplicator 6 Plus | Creality CR-10 | ||

| Wanhao Duplicator 9 | MakerBot Replicator 5th Gen | ||

| Monoprice Maker Select 3D Printer v2 | MakerBot Replicator Mini | ||

| Monoprice Maker Select Plus | MakerBot Replicator z18 | ||

| Cocoon Create 3D Printer | CraftBot 2 | ||

| CraftBot Plus | |||

| Ender 3 | |||

| BQ Witbox | |||

| BQ Prusa I3 Hephestos | |||

| Robo R1 | |||

| Robo R1 +PLUS | |||

| RoboC2 | |||

| RoboR2 | |||

| Wanhao i3 Mini | |||

| Wanhao Duplicator 4S | |||

| FlashForge Creator Original | |||

|

3D Printer Hotends |

||||

| Tungsten Carbide UM3 | Tungsten Carbide M6 3.00mm | Tungsten Carbide M6 High Flow 3.00mm | Tungsten Carbide M6 1.75mm | Tungsten Carbide M7 MK10 |

| Ultimaker Heatcore | Hexagon | e3D Volcano | Hexagon | MK10 |

| e3D | LulzBot | e3D | ||

| Olson Block | ||||

|

Not Compatible |

|||

| M6 3.50mm nozzles | Fine Thread | Female Thread | Fixed Heatbreak |

| Afinia H479 | WANHAO duplicator 5 | Printrbot Ubis | Phaetus Dragon Hotend |

| Afinia H480 | WANHAO Duplicator 5S | ||

| Up Plus | WANHAO Duplicator 5S MINI | ||

| Up Plus 2 | |||

| Up mini | |||

| Zortrax M200 | |||

10 reviews for Tungsten carbide nozzle

Related products

-

Thermistor 300°C/500°C

Rated 5.00 out of 5CA$13.00 – CA$35.00Price range: CA$13.00 through CA$35.00300°C and 500°C Thermistor assembly. Black Sleeve Molex Mini Fit Jr connector, Black Sleeve Molex SL connector or white sleeve (300°C).

Select options This product has multiple variants. The options may be chosen on the product page -

Alucore Replacement

CA$13.00 – CA$19.00Price range: CA$13.00 through CA$19.00Alucore Replacement Part for DyzEnd-X and DyzEnd Pro Hotends.

Select options This product has multiple variants. The options may be chosen on the product page

Julie Gagnon (verified owner) –

Extrudes nicely and prints great! Gives peace of mind about nozzle lifetime with abrasive filaments. Using it for printing with glow in the dark PLA, excited to also explore wood, metal, and carbon fiber filaments now.

Axel (verified owner) –

🙂 all fine.

thanks

Kingsland Dawson (verified owner) –

Printed a few parts with Carbon Fiber! So far…so good!

James Maaskant (verified owner) –

I would place these nozzle at the top quality of any nozzle on the market

Thomas Lippus (verified owner) –

The nozzles work very well, especially with metal powder filled filament. The only criticism is that the M6 thread is 0.5mm shorter than the original E3D nozzles. Therefore, the counter thread of the heatsink must be screwed a little deeper into the heating block to ensure sealing.

Peter Fuhren (verified owner) –

Perfect product!

Perfect customer service.

Excellent shipment/-speed

I didn’t dare to use some filament due to the abrasive nature. With this nozzle, I print whatever I want/like.

Somewhere it says that you can even print faster. That’s something I didn’t experience yet.

If it weren’t for the expensive shipping to Europe (and taxes/customs on top of it (>100% extra)), I’d order even two larger ones.

Brian Skoog –

I received my nozzle in october 2019, and after over a year of continuous use, here are my findings:

It’s awesome. 100% recommend, never going back to brass (why should I?). I’ve thrown multiple rolls of abrasive filament (carbon fiber, glow in the dark, stone fill, and metal fill) through the nozzle and have seen zero change in performance. Plus, due to the thermal conductivity of tungsten carbide, it was a drop-in change with brass and no settings needed to be adjusted.

If the performance so far is indicative of future performance, this may be the last nozzle I ever need on my machine. Buy one, it’s worth the price.

Mike (verified owner) –

I would echo Brian’s review above, completely. We have these nozzles (MK10, M7 thread) on several printers, and have printed everything from PLA to metal-filled specialty filaments with ZERO CHANGE IN PERFORMANCE in over a year. In addition, the tip shape (external) of the nozzle (the tungsten insert) has a much sharper profile than the typical, uniform taper of a brass nozzle. That, coupled with the more ‘slippery’ characteristics of the nickel plating,, almost eliminates any molten filament adhering to the hot nozzle, which virtually eliminates the age-old problem of dragging molten globs of filament build-up across an active print. These may very well be the LAST NOZZLES WE EVER HAVE TO BUY (until we get more printers, that is!) THIS IS AN EXCELLENT PRODUCT.

Alex (verified owner) –

Unfortunately very disappointing. I experienced reduced throughput of at least 15% with plain PLA compared to the A2 tool steel nozzle (some filaments were much more!) I definitely did not see the 80% increase claimed in the marketing materials. I tried adjusting temps and rechecked the z-offsets, I even refit the nozzle just in case i didn’t seat it correctly the first time. I couldn’t print successfully with glass-filled PLA, carbon fiber PETG, or even plain PETG (all of which have no issues running through the A2 steel nozzles. After wasting a ton very expensive filament and a lot of time, I switched back to the A2 nozzle.

Tom Hsia (verified owner) –

I got the 0.4mm M6 tungsten carbide nozzle back in 2020 and it has suffered 0 wear after going through kilos of carbon fibre and kevlar fibre filament. The 0.4mm nozzle I got had an orifice that was around 0.47mm instead of 0.4mm, which caused some problems like stringing and holes in the surface of the print. On the plus side, my “0.4mm” nozzle has suffered 0 clogs.

A cold pull revealed that this nozzle has a very good internal profile despite the two piece contruction, and it shows during printing. My “0.4mm” nozzle is nearly as performant my E3D 0.6mm plated copper nozzle and can be daily driven as a 0.6mm with 0 tuning (even for ABS filament with a 20% carbon fibre load). The flow performance of this nozzle is excellent, I’ve done vase mode prints at 1.6mm extrusion width with 0 problems. Since I’m using my “0.4mm” nozzle as a 0.6mm nozzle, I’m getting better surface finish than I would have with a regular 0.6mm nozzle. The nickle plating works well to prevent plastic from sticking.

Aside from the oversized orifice (which I believe only effects the 0.4mm version, at least back in 2020), I consider this the perfect nozzle. Flow performance is great, probably as good as a brass nozzle one size up, durability is extremely high, it stays quite clean, and it leaves a good finish on the top layer. I hope they fixed the orifice size, I would definately get another one if they did.