DyzeXtruder GT Extruder

Print. Stronger.

The combination of a reduction gear, dual pinch system, and unique all-metal design enables the DyzeXtruder GT to push as much as 9 kg (20 pounds) of force. This is more than necessary for all 3D printing applications. Still, the DyzeXtruder GT is a lot lighter than a traditional extruder with a planetary gearbox, allowing for faster printer accelerations.

Only CA$205

Designed for advanced printing

High pushing force

The combination of reduction gear, dual pinch and unique design enables the DyzeXtruder GT to push as much as 9 kg (20 pounds) of force. This is more than necessary for all 3D printing applications.

Unique Teeth Design

Unique designed teeth pattern on the driving system for maximum grip, no filament slipping and constant flow.

Dual pinch drive system

The dual-pinch system allows a higher pushing force with a lower filament pressure. It reduces the risk of flattening the filament when highly detailed prints require a lot of retractions.

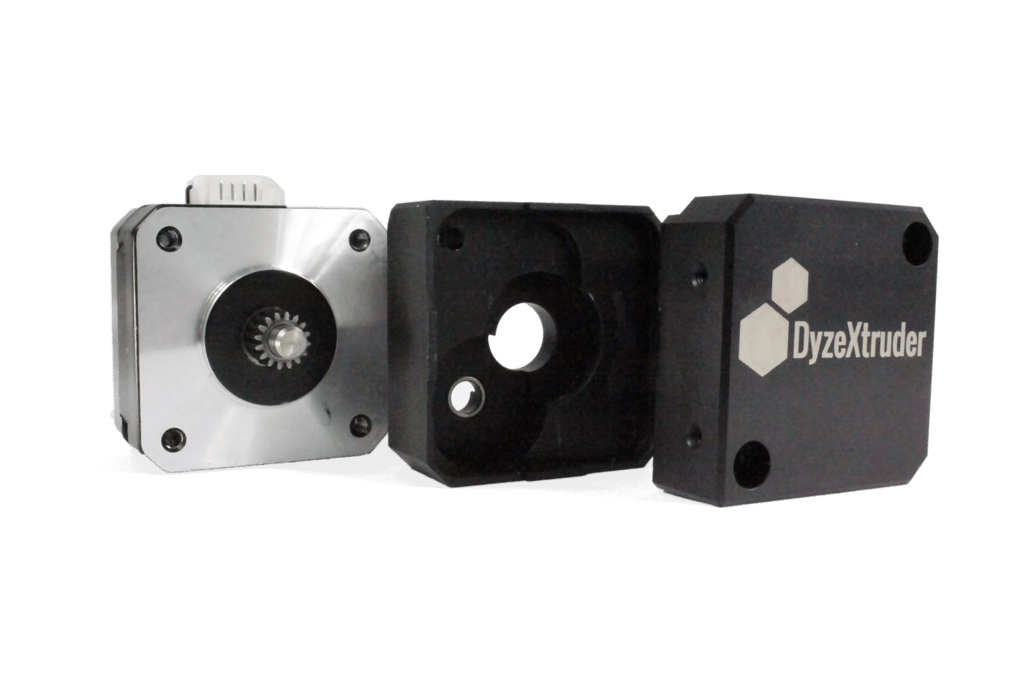

Protected Gears

All gears are protected inside housing to prevent any damage caused by dust and dirt.

Matched included motor

The included motor is chosen to match the maximum torque tolerated by filaments. The motor won’t grind your filament and will prevent any damage inside the extruder.

Small Form Factor

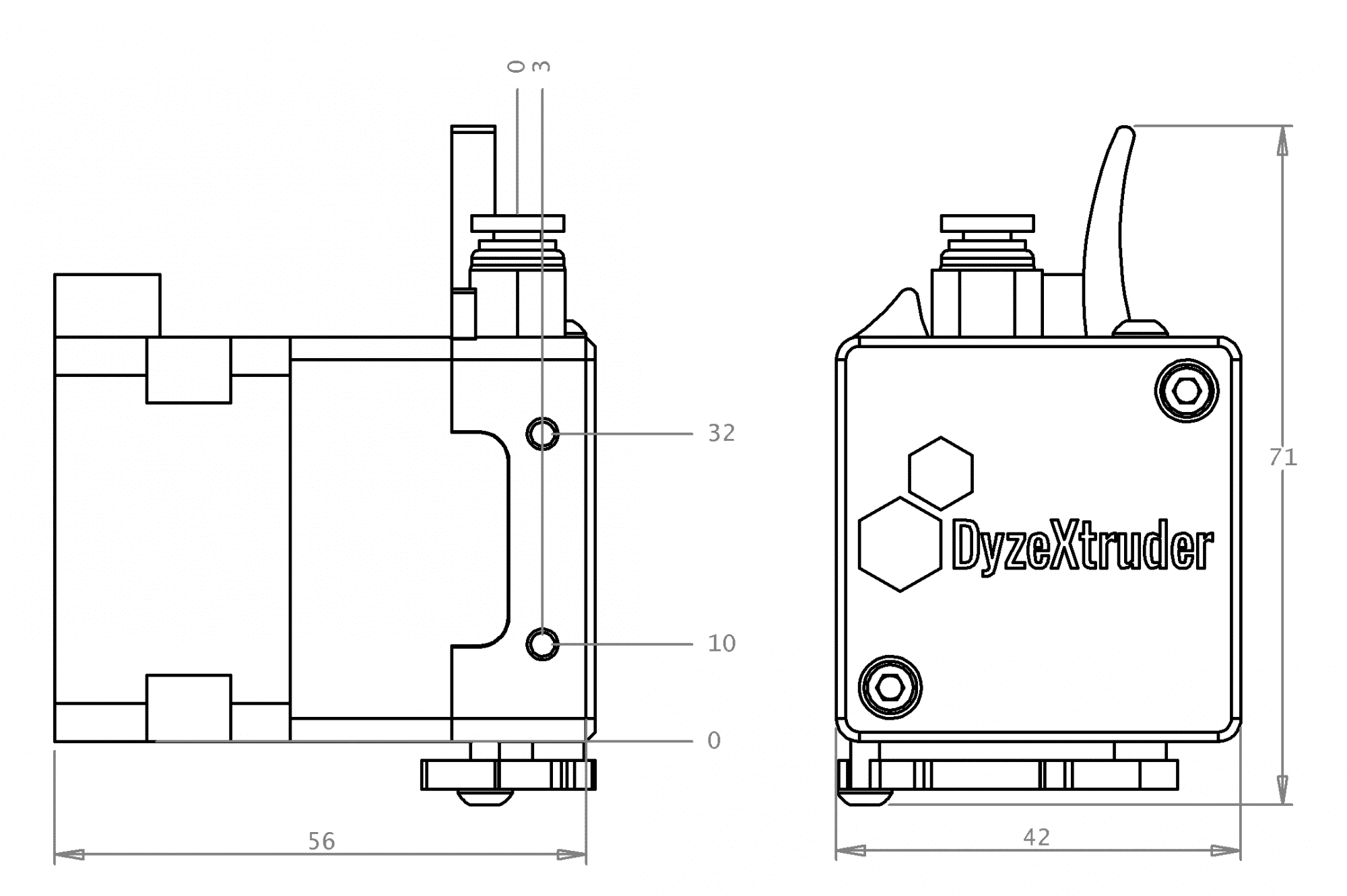

The DyzeXtruder GT is not larger than the NEMA 17 it uses, making it very space efficient on a multiple extruders configuration and one of the smallest on the market. Saving space on a carriage can allow you to print larger parts on a single printer.

Lightweight

The gear ratio was chosen to get the best of a very small motor.The DyzeXtruder GT is a lot lighter than a traditional extruder with a planetary gearbox, allowing for faster printer accelerations.

All metal

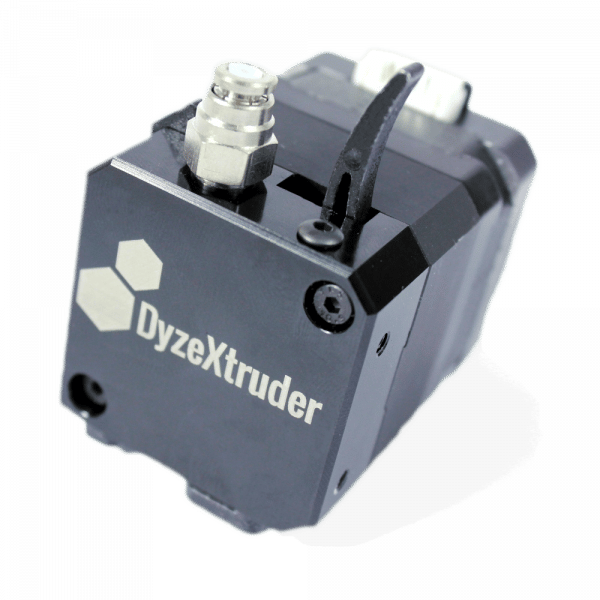

The aluminum housing is designed to offer a reliable operation, even in a high temperature environment.

Liquid Cooling Ready

The DyzeXtruder GT can be easily converted to a liquid-cooled setup with Dyze Design’s specialized cooling blocks.

Bowden Ready

The DyzeXtruder GT always comes with a special push to connect fitting. A PTFE tube can be inserted through the connector to guide the filament as far as possible inside the mechanism. A single modification in the firmware can easily transform a direct drive setup into a bowden.

Bracketless

The side mounting threads make it very easy to assemble; two M3 screws are included to fit the DyzeXtruder GT on a printer.

Metal Reduction Gears

The DyzeXtruder GT has a 5.65 : 1 gear ratio. This ratio has been chosen to use the full potential of a very small motor while, enabling very high pushing forces. The gears are custom made from high strength hardened steel. This combination allows low friction operations and a longer life. The gears and bearings are designed to last for hundreds of kilograms in extreme conditions.

Easy hotend swapping

The hotend locking mechanism is very practical and rigid.You can secure the hotend in place with only a screw. You can remove it even if there is still a filament inside the extruder due to its turning mechanism. No more hassle of disassembling your setup when you need to maintain your printer.

Easy filament removal and insertion

The unique lockable lever makes filament change very easy and convenient. The locking mechanism holds the lever in position while you change the filament. After, simply push back the lever to disengage the locking mechanism.

Connectors

The DyzeXtruder GT comes with a connector and a cable for its motor so you can easily maintain it.

Typical Performance Characteristics

DyzeXtruder-GT Push Force (kg) vs other popular brands

Print any plastics

The DyzeXtruder-GT is able to print every single type of plastic filaments currently sold on the market

Technical Information

| Parameter | Value |

| Weight | 275g |

| Filament diameter | 1.75mm |

| Operating current | 1A |

| Operating temperature (air cooled) | 0°C to +60°C |

| Operating temperature (liquid cooled) | 0°C to +120°C |

| Top fitting tube OD | 4.00mm |

| Gear ratio | 5.65 : 1 |

| Groove mount head thickness | 2 – 5mm |

| Mounting screw thread | M3 |

| Mounting screw min thread depth | 5mm |