- Industrial Controllers

- Pellet Extruders

- High-Flow Extruders

- Other Products

- Online Store

- Support

-

-

Need more help ?

If you’re having technical issues with one of your Dyze Design product and can’t find what you’re looking for in our installation and guides section, open a ticket and our support team will help you.

-

- Blog

-

Recent Posts

Filament Innovations Aligns with Dyze Design to Revolutionize Additive Manufacturing in the O&P Industry

Filament Innovations Aligns with Dyze Design to Revolutionize Additive Manufacturing in the O&P Industry Flow-To-RPM Factor: Optimize Your 3D Printing with Pellet Extruders

Flow-To-RPM Factor: Optimize Your 3D Printing with Pellet Extruders What is the best Dyze extruder and hotend for your application?

What is the best Dyze extruder and hotend for your application? Webinar – Increase Your Profitability With High-Flow Material Extrusion 3D Printing

Webinar – Increase Your Profitability With High-Flow Material Extrusion 3D Printing The Adverse Effects of PTFE Restrictions

The Adverse Effects of PTFE Restrictions

-

Zephyr™ High Flow Extruder

Revolutionizing High-Speed 3D Printing

Welcome to a new era of additive manufacturing, where excellence in extrusion technology meets savings in time and money. Dive into the next generation of 3D printing with the Zephyr™ extrusion system, boasting one of the highest volumetric flow rates on the market for 1.75mm filament.

At the heart of Zephyr™ lies the unique MeltCore™ technology, designed to ensure consistent melting and faster flow rates, enhancing the overall printing efficiency. Its lightweight design, coupled with advanced features like powerful 140W heater, filament tension adjustment and double grip mechanism, enables Zephyr™ to deliver unmatched performance. By optimizing the extrusion efficiency, Zephyr™ not only saves time but also reduces operational costs, making it an indispensable tool for those seeking to maximize productivity and cost-effectiveness.

From CA$1,750

Secure Your Zephyr™ Now

Don't miss the opportunity to experience high speed and high flow 3d printing like never before. Secure your Zephyr™ printhead today.

Simply fill out the form below to request a quotation and be ready to change your 3d printing.

Unmatched High-Flow Performance

The Zephyr™ High Flow Extruder sets a new standard in 3D printing. With a volumetric flow rate of 685 grams per hour (154 mm³/s) for 1.75mm filament, it offers unparalleled efficiency and speed, making it one of the fastest extruders on the market.

With a maximum heating temperature of 450°C, Zephyr™ can handle high-temperature materials such as PEEK and PEI. This expands the range of possible applications, making it a versatile tool for advanced printing needs.

Superior Quality and Performance

Say Goodbye to Extrusion Challenges

Zephyr™ High Flow Extruder enhances 3D printing by delivering consistent extrusion performance. This ensures that the material is evenly fed, resulting in dependable and high-quality prints. Enjoy superior results without the need for constant adjustments or reprints. Zephyr™ streamlines the printing process, saving time and boosting productivity.

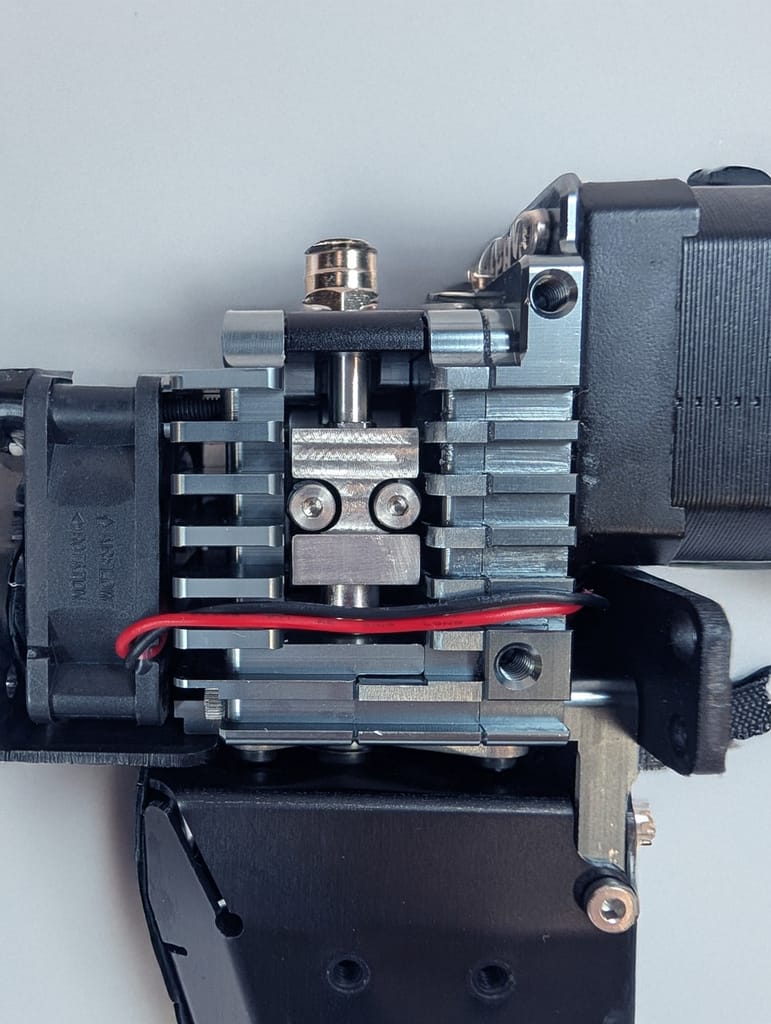

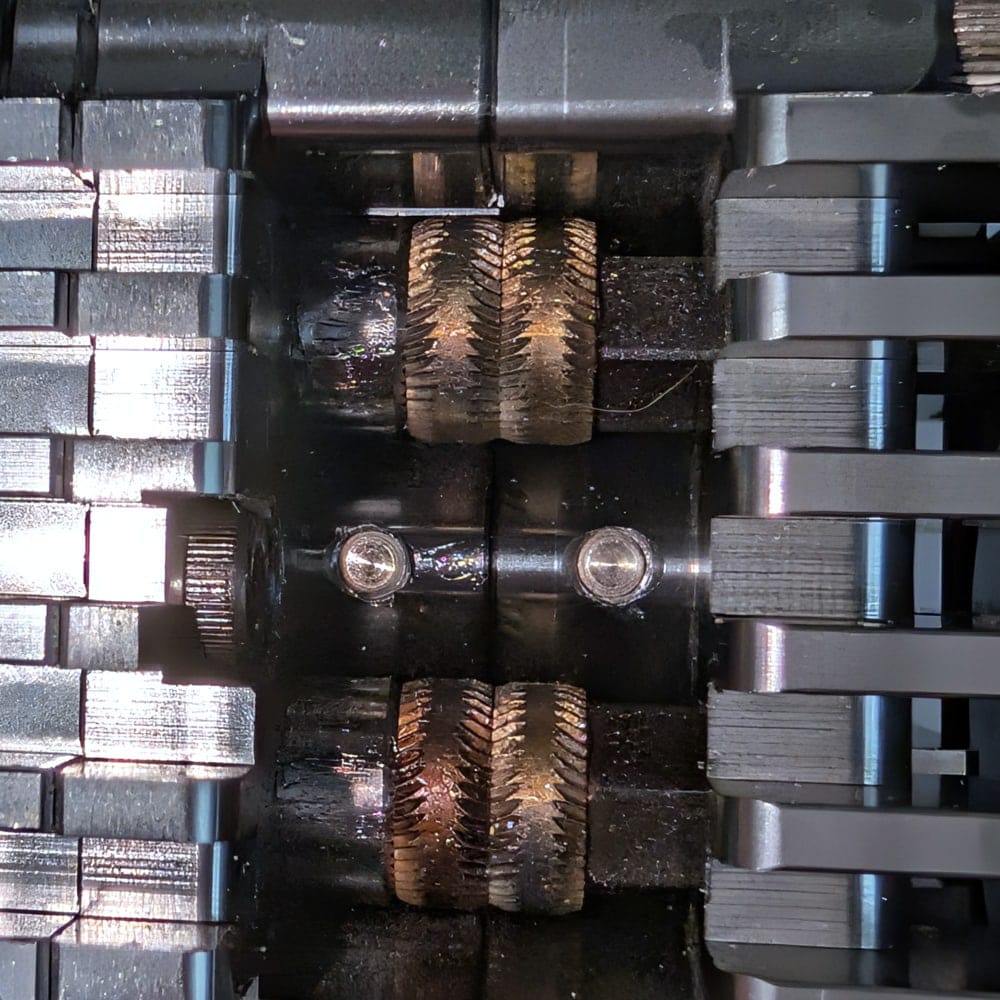

Double Grip Mechanism

The innovative double grip technology enhances filament traction, reducing slippage and improving feeding accuracy, crucial for consistent extrusion and print quality.

Filament Tension Adjustment

The system's filament tension adjustment feature, with nine settings, accommodates everything from flexible to oversized filaments, ensuring optimal extrusion for each material type.

Precision Gear Ratio

With a 3.1:1 gear ratio, the system provides a perfect balance between speed and torque, accommodating a wide range of printing needs.

Powerful Heating Power

The powerful 140W heater and PT100 sensor enable precise temperature control and faster heat-up times, ensuring optimal extrusion conditions for each material type.

Seamless Integration

Optimize Your 3D Printing Process

The Zephyr™ High Flow Extruder offers unmatched adaptability and precision. With a lightweight design, versatile nozzle options, and universal material compatibility, it seamlessly integrates into any printing environment. Whether you’re working on detailed prints or high-speed production, Zephyr™ adapts to your needs, enhancing efficiency and performance.

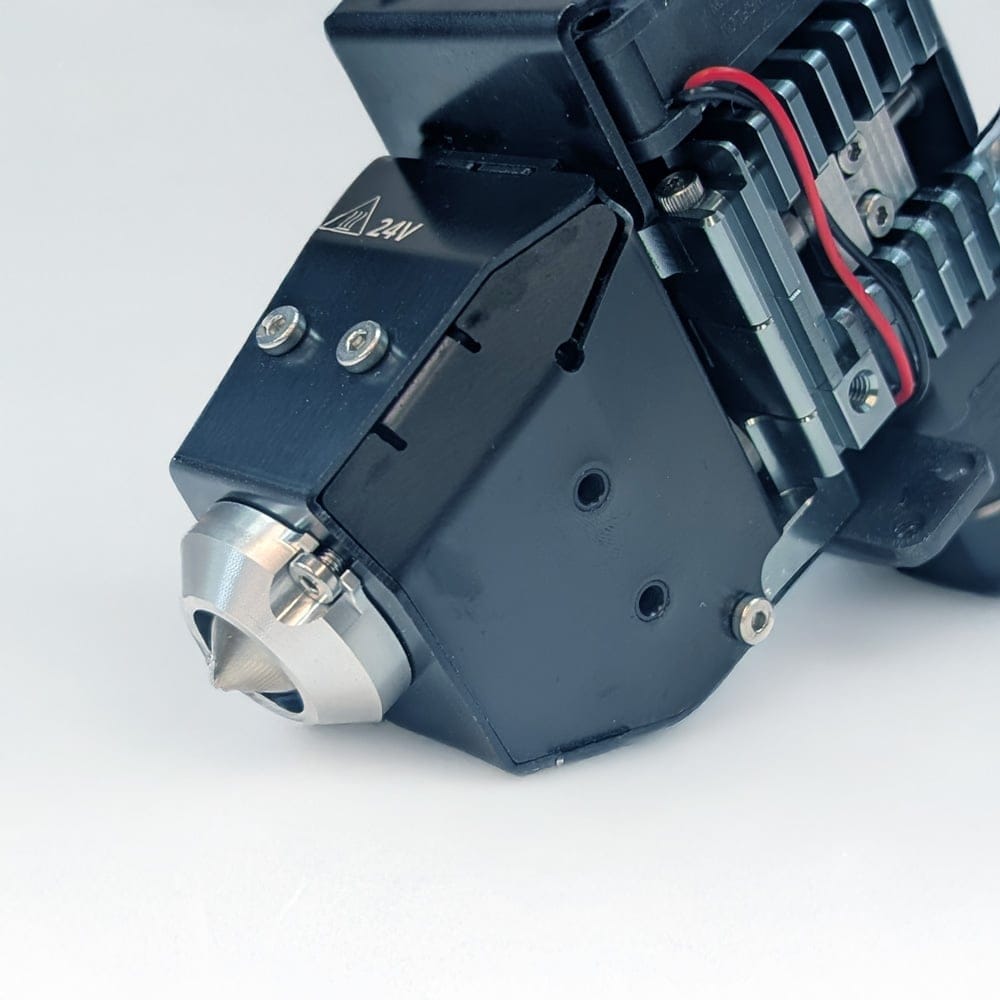

Lightweight Design

Weighing in at around 700g, the Zephyr™ system offers unparalleled portability for such a high-flow extruder, making it ideal for various operational environments without compromising performance.

Versatile Nozzle Options

With nozzle sizes ranging from 0.4mm to 2.5mm, Zephyr™ is adaptable for detailed prints or rapid throughput, ensuring versatility across various printing tasks.

Universal Material Compatibility

Zephyr™ is designed to work with all printable materials, including elastomers, high-temperature polymers, and standard filaments, making it a versatile choice for any printing project.

Easy Maintenance

Designed with user experience in mind, Zephyr™ offers easy access to its internal components for maintenance and cleaning, ensuring long-term reliability and performance consistency.

Innovative MeltCore™ Technology

At the core of Zephyr™ is our revolutionary MeltCore™ technology. This ensures consistent melting and faster flow rates, enhancing overall printing efficiency. The advanced 140W heater and PT100 sensor provide precise yet powerful temperature control, essential for high-quality prints.

Technical Information

| Parameter | Specification |

|---|---|

| Weight | ±700g |

| Dimensions | 47.3mm x 104.1mm x 123.7mm |

| Flow Rate (Output Flow)* | 685g per hour 154 mm3/s |

| Nozzle Sizes | 0.4mm, 0.6mm, 0.9mm, 1.2mm, 1.8mm, 2.50mm |

| Voltage | 24VDC |

| Max Environment Temperature | -10°C ~ 60°C |

| Max Operating Temperature | Up to 450°C |

| Compatible Material | All printable filament materials. 1.75mm diameter. |

*Maximum flow rate with PLA @ 260°C with 1.80 mm nozzle.