- Industrial Controllers

- Pellet Extruders

- High-Flow Extruders

- Other Products

- Online Store

- Support

-

-

Need more help ?

If you’re having technical issues with one of your Dyze Design product and can’t find what you’re looking for in our installation and guides section, open a ticket and our support team will help you.

-

- Blog

-

Recent Posts

Filament Innovations Aligns with Dyze Design to Revolutionize Additive Manufacturing in the O&P Industry

Filament Innovations Aligns with Dyze Design to Revolutionize Additive Manufacturing in the O&P Industry Flow-To-RPM Factor: Optimize Your 3D Printing with Pellet Extruders

Flow-To-RPM Factor: Optimize Your 3D Printing with Pellet Extruders What is the best Dyze extruder and hotend for your application?

What is the best Dyze extruder and hotend for your application? Webinar – Increase Your Profitability With High-Flow Material Extrusion 3D Printing

Webinar – Increase Your Profitability With High-Flow Material Extrusion 3D Printing The Adverse Effects of PTFE Restrictions

The Adverse Effects of PTFE Restrictions

-

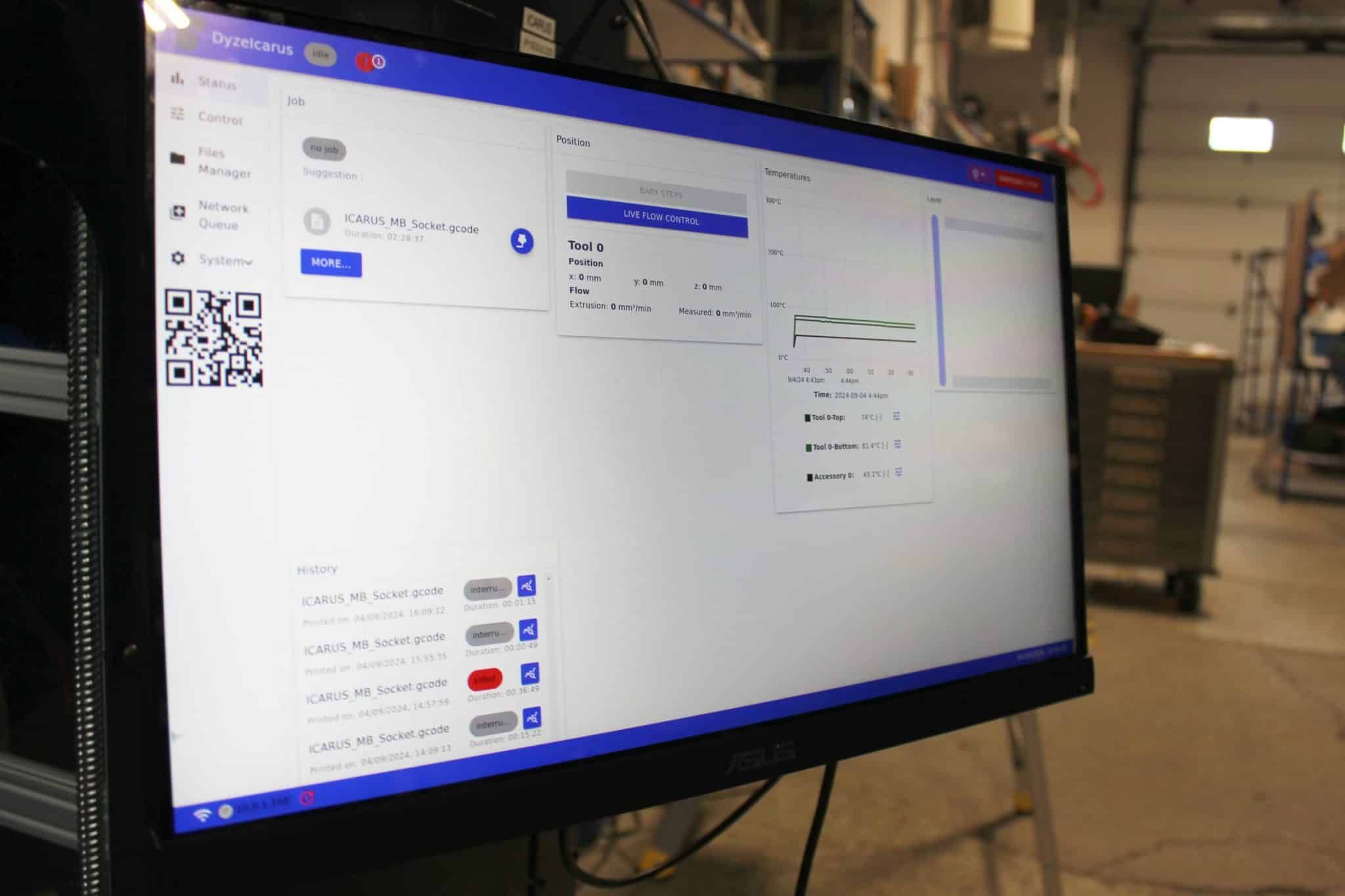

Unleash Precision and Control with Aurora™: The Next-Gen Industrial Motion and I/O Controller

Revolutionize your 3D printing process with unmatched precision, real-time data insights, and seamless integration into any machine.

A new Standard in 3D Printing

Aurora™ is more than just an industrial motion and I/O controller—it’s a game-changer for 3D printing and industrial automation. Designed with professionals and industries in mind, the Aurora ecosystem offers advanced control, precise motion, and unparalleled real-time data insights that elevate your manufacturing capabilities.

Whether you’re looking to reduce failed prints, optimize processes, or gain deeper insights into your production, the Aurora™ provides the tools and intelligence needed to transform your workflow and pushes the boundaries of what’s possible in additive manufacturing.

Revolutionize Your 3D Printing Workflow

Advanced Feedback, Insights, and Automation for Flawless Prints

Aurora’s innovative technology brings precision and reliability to 3D printing. Our 2-Stage Position Feedback system keeps each motor in sync, enhancing quality and minimizing errors. With Cloud Analysis and Reporting, gain insights, track performance, and set real-time thresholds for optimized prints. Finally, the Reactive Motion Planner adapts dynamically to maintain consistent print quality with minimal intervention. Aurora ensures dependable, high-quality 3D printing every time.

Unique 2-Stage Position Feedback

Achieve precise and synchronized motion control with Aurora’s unique 2-stage position feedback system. Each motor operates with its own feedback loop, while a second layer of synchronization ensures smooth operation and quick problem detection, reducing errors and enhancing print quality.

Cloud Analysis and Reporting

Leverage powerful cloud-based analytics to gain insights into every print. Aurora’s cloud analysis feature provides detailed post-print reports, 3D visualizations, and PDF summaries that help you optimize processes, set thresholds, and validate parts in real-time.

Reactive Motion Planner

Experience seamless, automatic adjustments with Aurora’s Reactive Motion Planner. Built specifically for 3D printing, this planner responds dynamically to changes, automatically pausing, adjusting flow, speed, or fan settings to ensure optimal print quality with minimal manual intervention.

How It Works

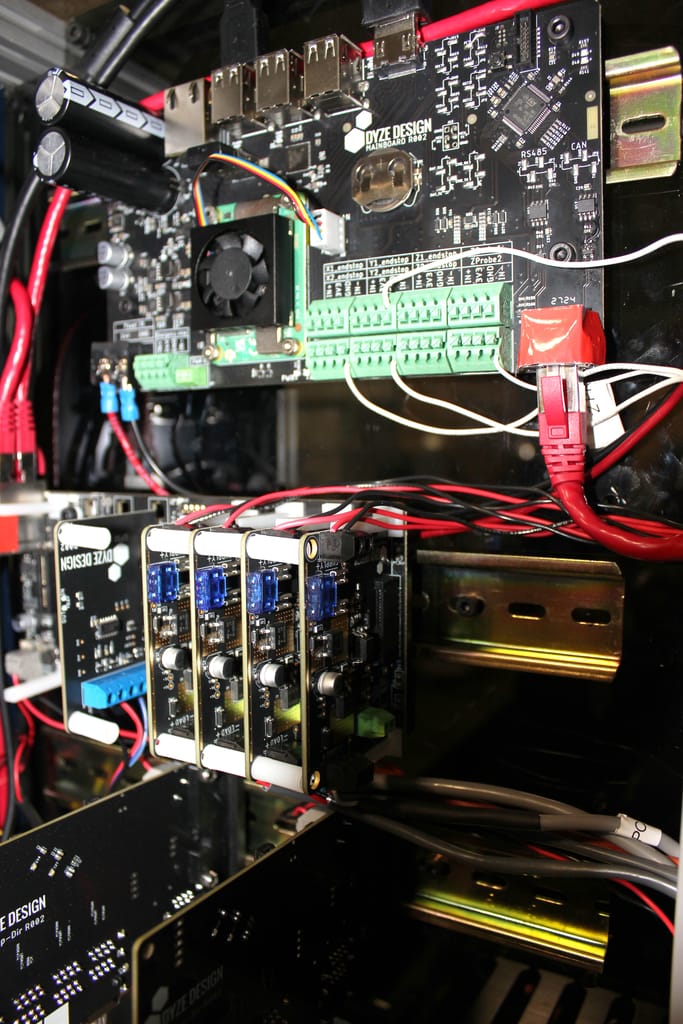

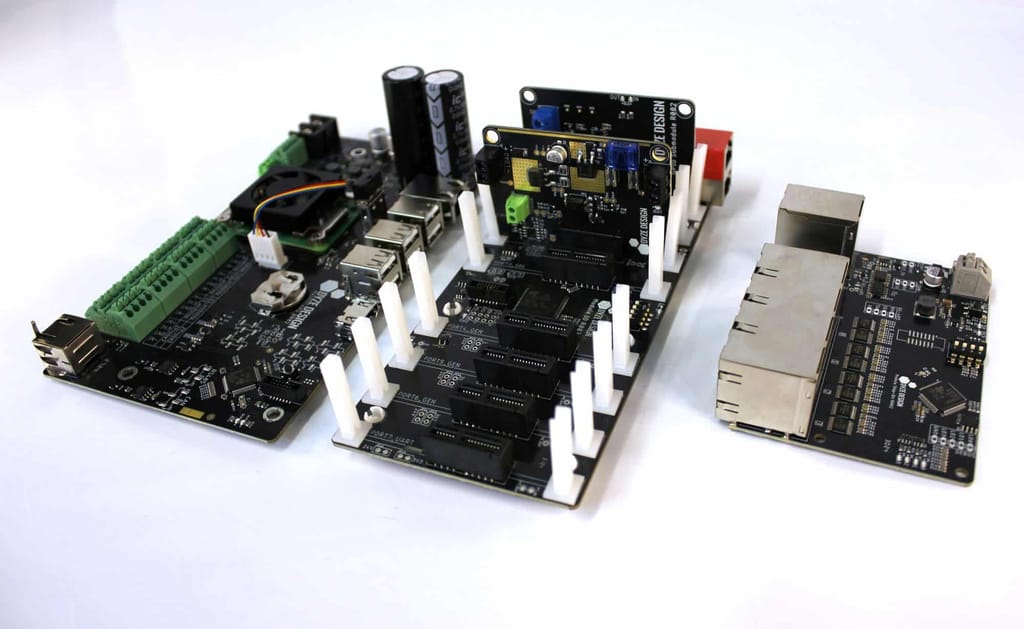

Seamless Setup

Aurora replaces your existing controller with an all-in-one solution featuring a real-time motion controller and operating system. It’s easy to set up—add-on boards are daisy-chained to handle your printer’s IO and features. The intuitive ecosystem automatically detects components and imports existing configurations to streamline the process. With a few quick calibration tools, your machine is ready for its first print.

Effortless Integration

Aurora fits right into your current workflow. It accepts GCode from any slicer and works seamlessly with standard 3D printing hardware, including steppers, servos, lasers, capacitive sensors, and multi-zone extrusion systems. No need to change anything—just plug and print.

Advanced Motion Control

Aurora’s third-order polynomial S-Curve ensures smooth, precise movements, syncing motors every 1 ms for maximum precision. Manual adjustments are integrated at a low level, allowing for rapid machine responses and seamless pauses when necessary.

Cloud Analysis with One Click

Once a print job is complete, it can be sent to the cloud for detailed analysis and reporting with a single click. Access performance insights and generate reports instantly from the cloud interface.

Smart Problem Detection

Aurora detects issues in real-time using sensor data. Custom thresholds can be set, allowing you to spot problems quickly and react before they escalate—minimizing downtime and maximizing print success.

Simple Customization and Updates

OTA updates are controlled by the manufacturer, and clients can apply them with a single click when ready. Customizing the interface is just as easy—upload a logo, select your colors, and personalize the system to reflect your brand.

Frequently Asked Questions

1. What is Aurora and how does it work?

Aurora is an industrial motion and IO controller designed to replace your existing 3D printer controller. It features a built-in real-time motion controller and operating system, making it an all-in-one solution for advanced control and monitoring of your machines.

2. How difficult is it to set up Aurora?

Setup is simple and intuitive. Aurora automatically detects components connected to its network, and existing configurations can be imported to speed up the process. The UI-driven configuration process and built-in calibration tools make setup straightforward, even for complex machines.

3. Will Aurora work with my current 3D printer hardware?

Yes. Aurora is compatible with a wide range of standard 3D printer hardware, including steppers, servos, lasers, capacitive sensors, and both single and multi-zone extrusion systems. It accepts GCode from any slicer, so you won’t need to change your workflow.

4. How does Aurora improve motion control?

Aurora uses a third-order polynomial S-Curve motion planner for smooth, precise movements. Motors are synchronized every 1 ms, ensuring accuracy. The system allows for quick, responsive manual adjustments and seamless pauses when necessary.

5. How does the cloud analysis feature work?

Once a print is finished, the job can be sent to the cloud with a single click. From there, you can analyze performance data, generate reports, and view insights in an easy-to-use cloud interface.

6. Can Aurora detect problems during printing?

Yes. Aurora uses real-time sensor data to detect issues based on custom thresholds you set. If the process moves out of range, Aurora will alert you, helping to avoid print failures.

7. How are updates and interface customization handled?

OTA updates are managed by the manufacturer and can be applied with a single click when convenient. Customizing the user interface is also easy—simply upload your logo and select your preferred color theme.

8. Does Aurora support remote monitoring?

Yes. The Manufacturer Dashboard provides real-time machine status and performance metrics. You can plan preventive maintenance according to

Technical Information

| Parameter | Specification |

|---|---|

| Weight | Less than 1.5kg |

| Height | Less than 245mm |

| Flow Rate (Output Flow) | 800g per hour* |

| Nozzle Sizes | 0.4mm, 0.6mm, 0.9mm, 1.2mm, 1.8mm, 2.5mm |

| Voltage | 110V or 220V |

| Max Environment Temperature | Up to 150°C |

| Max Operating Temperature | Up to 450°C |

| Compatible Pellets | Shorter than 4mm** |

*Output flow data represents the latest achieved results from testing the alpha version. Please note that the actual output flow of the current release version may vary slightly

**Optimal performance is achieved with pellets that are 4mm or shorter, measured as the maximum (longest) straight-line distance from one end to the other.