DyzEnd Pro Hotend

High Speed.

High Flow. High Temp.

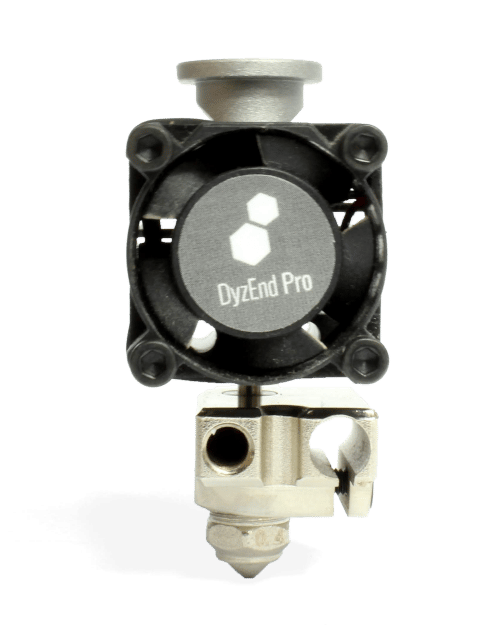

The DyzEnd Pro hotend has a really small form factor making it one of the smallest on the market. It is designed with a new high-temperature heat block, a new ceramic coated transition tube, vibration dampening feature, reinforced sealing properties, and smaller vibration resistant connectors that are better suited for 3D printers in closed environments.

Only CA$178

Designed for high-performance professional printing

Tungsten carbide nozzle

The DyzEnd Pro comes built in with ultimate durability and performance tungsten carbide nozzle. The high thermal performance of the tungsten carbide keeps the nozzle tip hot, thus allowing faster printing speed without sacrificing the quality. Tungsten carbide has exceptional wear resistance due to its high hardness.

New Ceramic Coated Transition Tube

The DyzEnd Pro is made from a ceramic coated titanium transition tube. The hard coating increases wear resistance and reduce friction, enabling easier retraction and better flow.

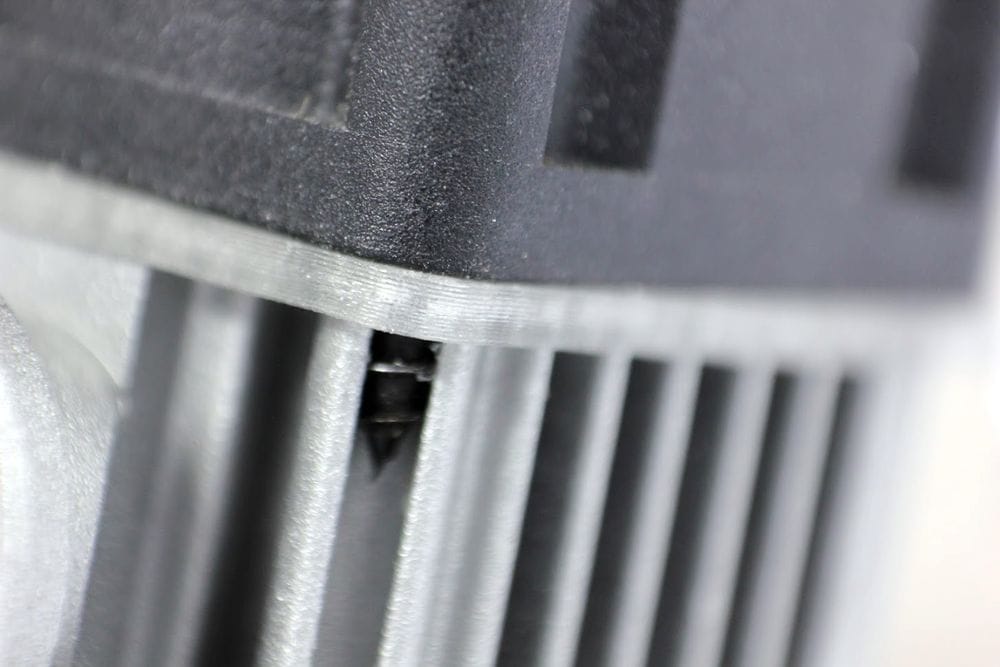

Fan sound/vibration dampening

The small rubber spacer absorbs the vibrations generated from the fan and reduces the noise. The higher quality fans have ball bearing, increasing lifespan and further reducing vibrations.

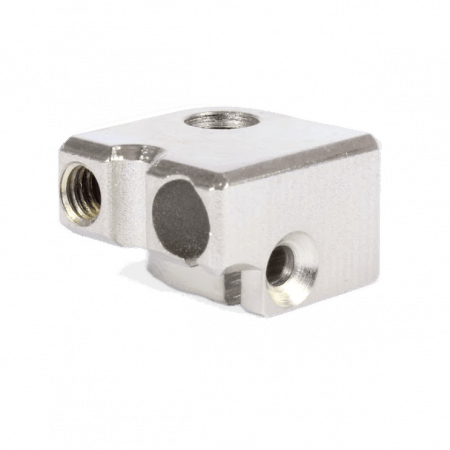

New High-Temperature Heat Block

Steel will keep its strength at high temperature much better than copper or aluminum. The new block shape reduce the losses by breaking the sharp edges. The coating is very slippery and easier to clean.

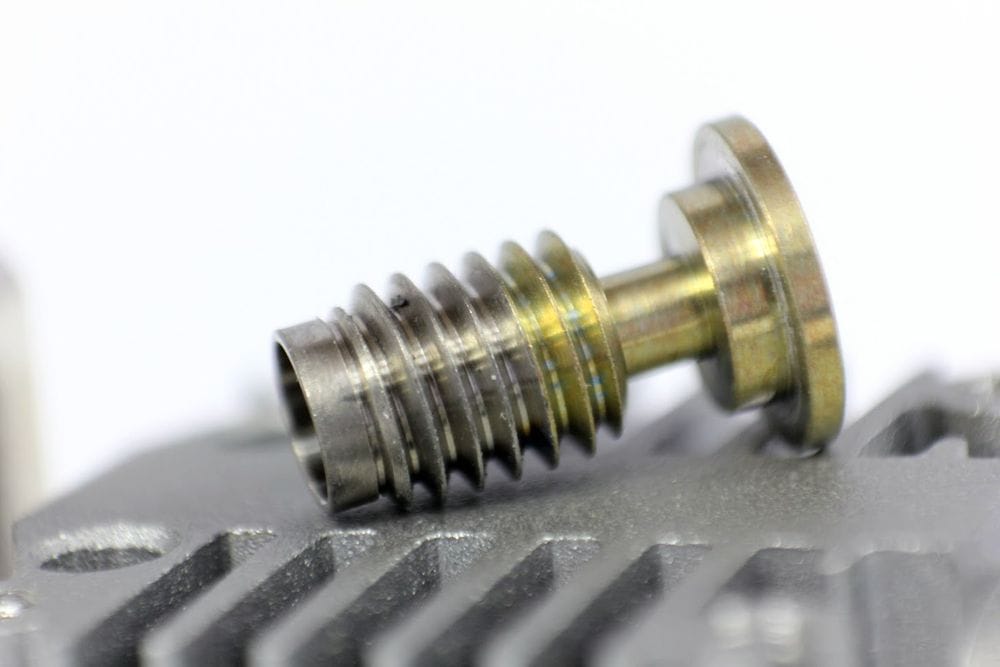

Inconel sealing washer

Inconel is heat-resistant alloys used in extreme environments. The sealing washer easily keeps its sealing properties, even at 500°C.

Any Temperature Sensor

Choose between a 300°C Thermistor, a 500°C Thermistor, a 500°C PT100, or a 500°C Type K thermocouple sensor.

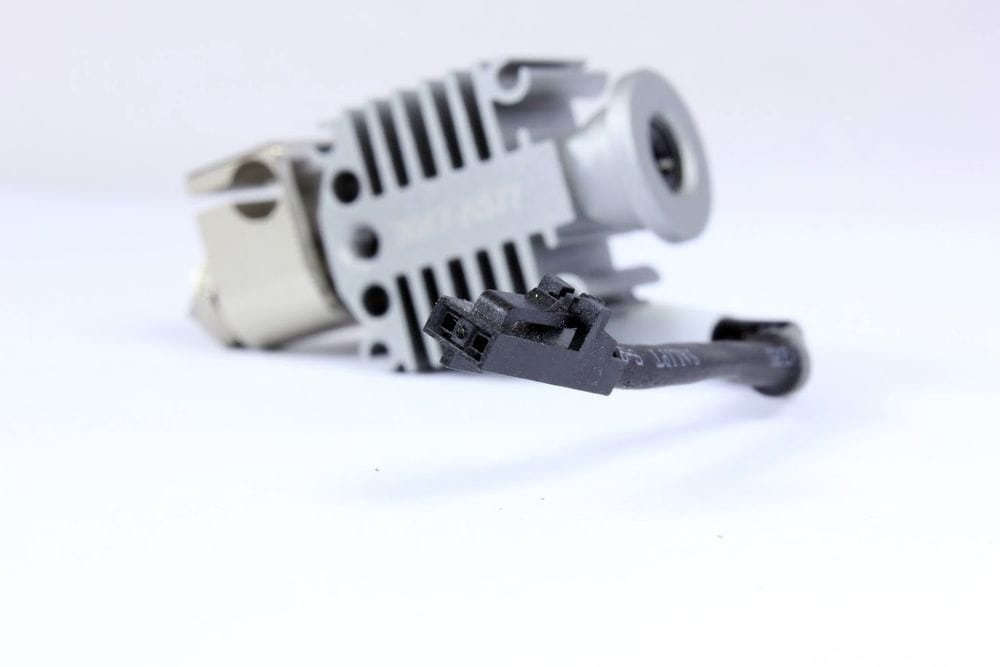

New connectors

Smaller, vibration resistant new connectors are better adapted for 3D printers environment.

Liquid Cooling Ready

The DyzEnd Pro can be easily converted to a liquid cooled setup with Dyze Design’s specialized cooling blocks.

Cold Swappable Nozzles

By using a very special high-temperature sealing washer and a very strong M10 nozzle, the DyzEnd Pro is able to switch nozzles at room temperature. No leaks, no burning hazard.

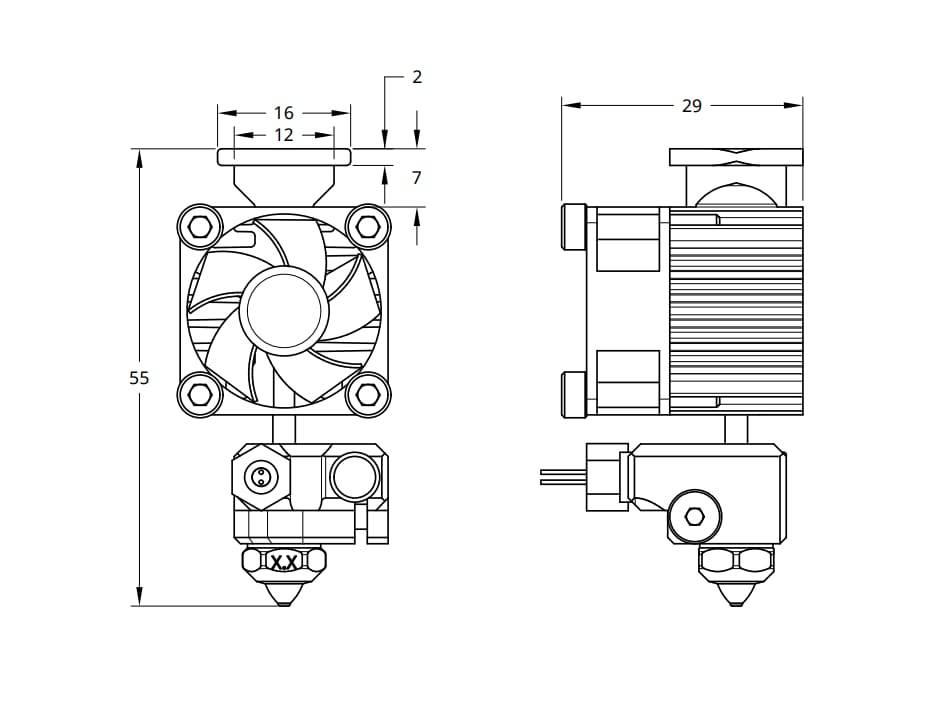

Small Form Factor

By using a low conductivity transition tube, the DyzEnd Pro is one of the smallest hotend on the market. This enables you to use your build volume more efficiently.

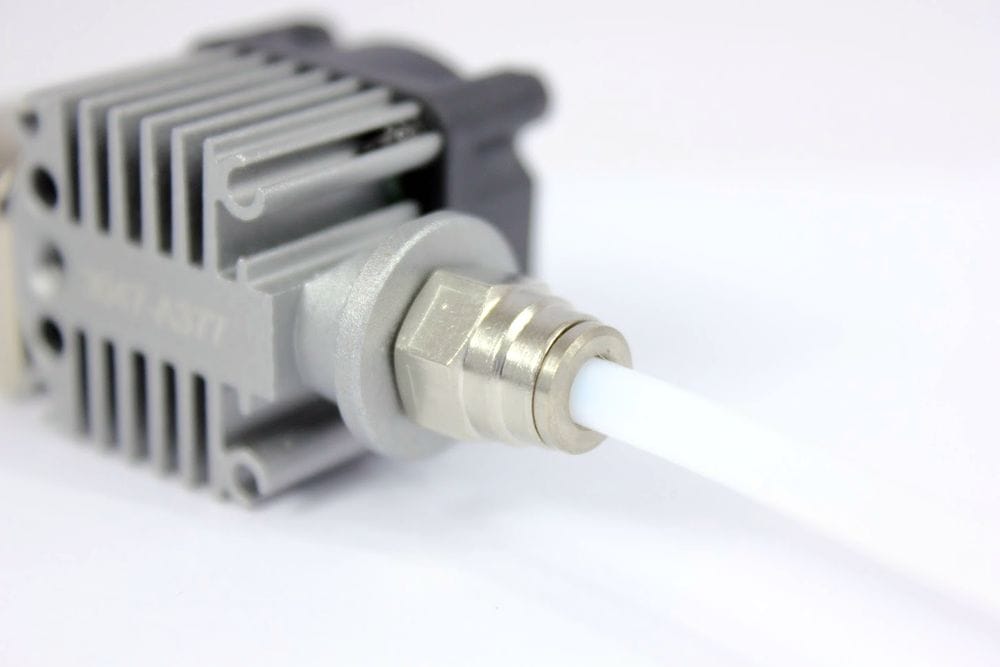

Bowden Ready

The DyzEnd Pro is compatible with a M8x1.25 push to connect fitting. The 4mm PTFE tube can be inserted through the connector and guides the filament as far as possible inside the hotend.

Groove Mount

The hotend mounting mechanism is based on the form factor called “Groove Mount”. The 12mm groove makes it very easy to switch and maintain your hotend and nozzle.

Rigorous Quality Control

Critical parts are under strict quality control upon reception and are 100% tested.

Our qualified assembling team has many tools for validating performance throughout the assembly process.

Print any plastics

The DyzEnd Pro is able to print every single type of plastic filaments currently sold on the market

Technical Information

|

Parameter

|

Value

|

Units

|

| Weight – Hotend | 52 | g |

| Operating Voltage | 12, 24 | V |

| Operating temperature | Up to 30 | °C |

| Operating temperature (liquid cooled) | Up to 120 | °C |

| Top thread | M8x1.25 | mm |

| Thermistor resistance at 25°C (500°C) | 4700 | kΩ |

| Thermistor resistance at 200°C (500°C) | 8 | kΩ |

| Maximum temperature – 40W | 420 | °C |

| Maximum temperature – 60W | 500 | °C |

| Maximum Flow Rate (1.2mm nozzle) | 25 | mm3/s |