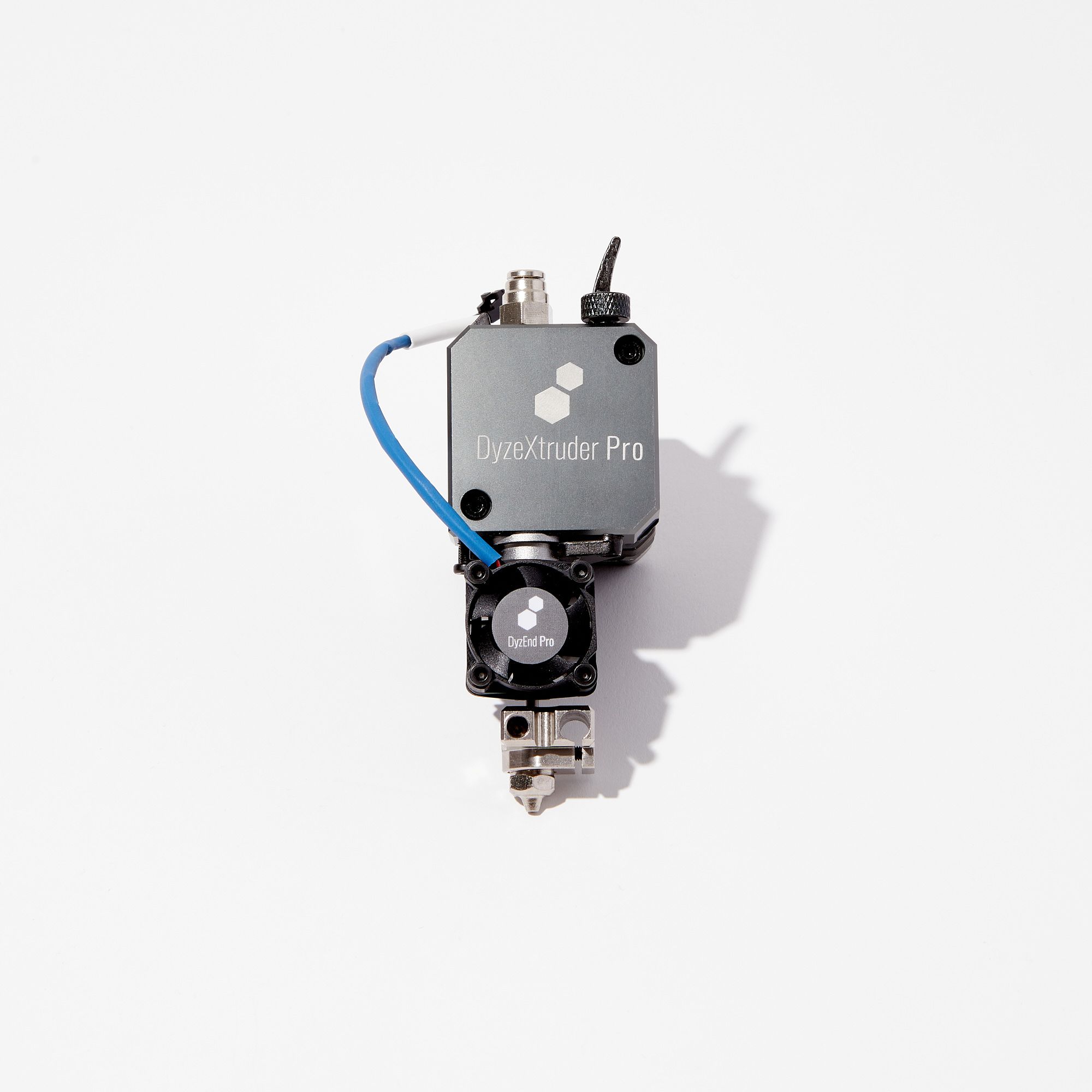

Kit DyzEND Pro + DyzeXtruder Pro 1.75mm

CA$452.00

Dyze Design’s Pro SerieExtruder & Hotend kit: High performance, high speed, high flow, high-temperature, and high pushing force. Equipped with an ultra wear resistant nozzle in tungsten carbide.

The DyzEnd Pro has a really small form factor making it one of the smallest hotend on the market. It is designed with a new high-temperature heat block, a new ceramic coated transition tube, vibration dampening feature, reinforced sealing properties, and smaller vibration resistant connectors that are better suited for 3D printers in closed environments. Moreover, the DyzEnd Pro comes equipped with Dyze Design’s new ultra wear resistance tungsten carbide nozzle. The high thermal performance of the tungsten carbide keeps the nozzle tip hot, thus allowing faster printing speed without sacrificing the quality. Tungsten carbide has exceptional wear resistance due to its high hardness.

DyzeXtruder Pro is lightweight and all-metal 3d printer extruder and also has one of the smallest form factors on the market: it is not larger than the NEMA 17 it uses, making it very space efficient on a multiple extruders configuration. Besides, the extruder is stronger than ever. With the improved teeth and new bearings types, the DyzeXtruder Pro is able to push as much as 10 kg (22 pounds) of force. This is more than necessary for all 3D printing applications. Finally, the new backblock has cooling fins for increased heat spreading in room environments.

DyzEnd Pro

New High-Temperature Heat Block: Steel will keep its strength at high temperatures much better than copper or aluminum. The new block shape reduces losses by breaking the sharp edges. The coating is very slippery and easier to clean.

New Ceramic Coated Transition Tube: The DyzEnd Pro is made from a ceramic coated titanium transition tube. The hard coating increases wear resistance and reduce friction, enabling easier retraction and better flow.

Fan sound/vibration dampening: The small rubber spacer absorbs the vibrations generated from the fan and reduces the noise. The higher quality fans have ball bearings, increasing lifespan, and further vibration reduction.

Cold Swappable Nozzles: By using a very special high-temperature sealing washer and a very strong M10 nozzle, the DyzEnd Pro is able to switch nozzles at room temperature. No leaks, no burning hazard.

Inconel® sealing washer: Inconel alloys are heat-resistant and can be used in extreme environments. The sealing washer easily keeps its sealing properties, even at 500°C.

Any Temperature Sensor: Choose between a 300°C Thermistor, a 500°C Thermistor, a 500°C PT100, or a 500°C Type K thermocouple sensor.

Liquid Cooling Ready: The DyzEnd Pro can be easily converted to a liquid cooled setup with Dyze Design’s specialized cooling blocks.

DyzeXtruder Pro

Toolless HotEnd Removal: Take your hotend off of your extruder in just a few seconds with the thumb screw. This will loosen the groove mount and free your hotend.

Multiple Mounting Possibilities: The side mounting threads make it very easy to assemble; two M3 screws are included to fit the DyzeXtruder Pro on a printer, bracketless. You can also mount the extruder on a panel.

Guided Filament: The guides conduct the filament out of the extruder. They follow the teeth shape, allowing no other exits for the filament. The whole part has a low friction coating, increasing the pushing efficiency.

Completely Redesigned Teeth: 35% more pushing force with rigid filaments. 25% more pushing for with flexible filaments. Also, the filament remains round, even after 100+ passages.

Metal Reduction Gears: The DyzeXtruder Pro has a 5.65: 1 gear ratio. This ratio has been chosen to use the full potential of a very small motor while, enabling very high pushing forces. The gears are custom made from high strength hardened steel. This combination allows low friction operations and a longer life. The gears and bearings are designed to last for hundreds of kilograms in extreme conditions.

Dual-pinch drive system: The dual-pinch system allows a higher pushing force with a lower filament pressure. It reduces the risk of flattening the filament when highly detailed prints require a lot of retractions.

Constant pressure: The custom spring has been redesigned to provide the optimal pressure at the filament with the new teeth. You’ll always get the same output flow, reducing the variations involved in changing filaments.

Matched included motor: The included motor is chosen to match the maximum torque tolerated by filaments. The motor won’t grind your filament and will prevent any damage inside the extruder.

- DyzEnd Pro Hotend equipped with Tungsten Carbide Nozzle

- Fan with connector

- DyzeXtruder Pro

- Heater with Connector

- Temperature Sensor with Connector

- Extension Cables

- 1000mm – Fan

- 1000mm – Heater

- 1000mm – Sensor

- 1000mm stepper motor cable

- BlackCable Tie

- Dyze Design Brand Stickers

- Additionnal Sealing Washer

- 2* M3x10 mounting screw

* Mounting bracket isn’t included. You can design your own or find some ideas from the community: https://www.yeggi.com/q/dyze/

4 reviews for Kit DyzEND Pro + DyzeXtruder Pro 1.75mm

Related products

-

DyzeXtruder Pro 1.75mm Extruder

Rated 4.67 out of 5CA$289.00High performance all metal extruder designed for high temperature and controlled environment. Powerful, lightweight and designed to work with any filament.

-

Kit DyzEND-X + DyzeXtruder GT 1.75mm

Rated 5.00 out of 5CA$315.00 – CA$339.00Price range: CA$315.00 through CA$339.00Dyze Design’s Extruder & Hotend kit: High Temperature, Fast print with High Pushing Force.

Select options This product has multiple variants. The options may be chosen on the product page -

DyzEnd Pro Hotend 1.75mm

CA$187.00High performance, high speed, high flow, and high-temperature 3d printer hotend. Equipped with ultra wear resistant nozzle in tungsten carbide.

Select options This product has multiple variants. The options may be chosen on the product page

William FitzPatrick (verified owner) –

Dyze design has a lot of things going for them. Something about their design is simply magical.

Cons:

-Longer filament travel path: heatsink really should be built into the gearbox housing like chinese BMG-aero designs, and the titan aero

-Price

-Overall height

-Weight

-Early units shipped with a defect

Pros:

-Very dedicated customer support. Even though my account had issues where my messages never sent to them and copies were never sent to my email. When they did find out they were relentless to make things right. I will admit it, with the amount of correspondence that went unanswered, I intentionally let their initial email slide. However they really wanted to make things right and followed up a day or two later.

-Very light for this style of extruder and hotend

-ceramic coating and chamfered mating points in filament path (This should eliminate any problems that could arise from a longer filament path)

-They properly used a bronze bushing in the drive chain were using a ball bearing could have conflicted with other parts and may not have had sufficient strength.

-Incredible extrusion strength

– Filament is not damaged by the hobbed gears

Christopher J Castro (verified owner) –

Would have given it a higher review but the PT100 sensor was dead on arrival.

Christopher J Castro (verified owner) –

Dyze sent me a PT100 replacement, now everything works fine! I have been printing almost non-stop and am quite impressed with the quality of my prints. You will have to spend some time calibrating everything so be patient. But once you dial in the proper settings and g-code, the results will be quite impressive! There is No jamming, no clogging no interruptions, just smooth printing. Its an expensive unit and can be quite frustrating to dial in, but its well worth it! Ive used 4 different extruder/hotends and this is by far the best.

MICHEL ASSANTE (verified owner) –

Cool simple design, great precision, strong metal alloy and interchangeable hot ends!