2024-05-30

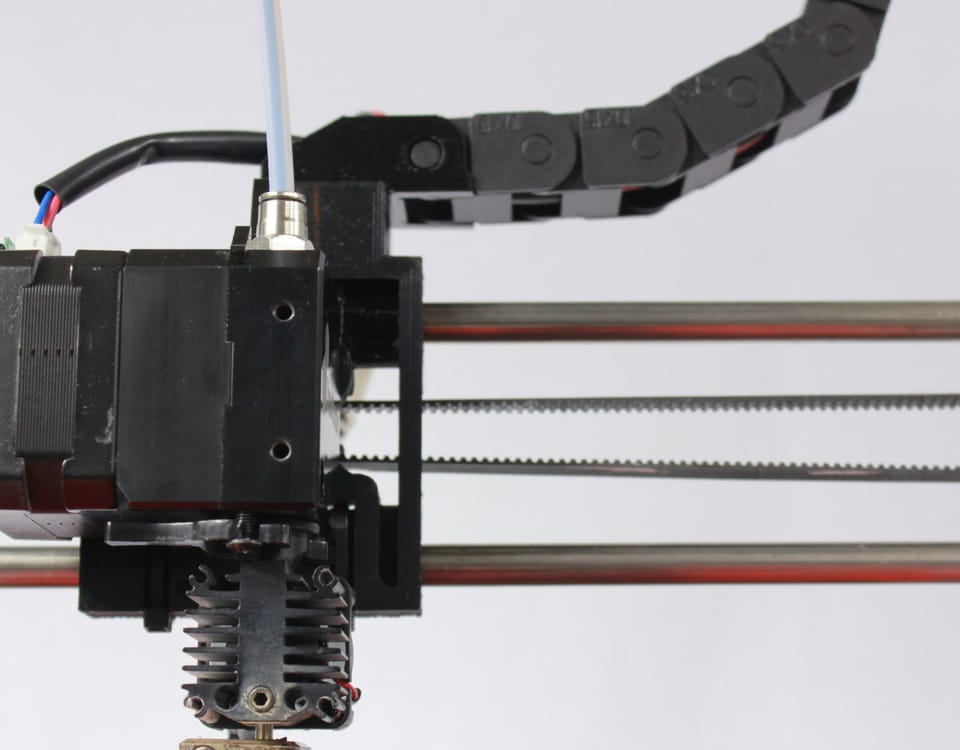

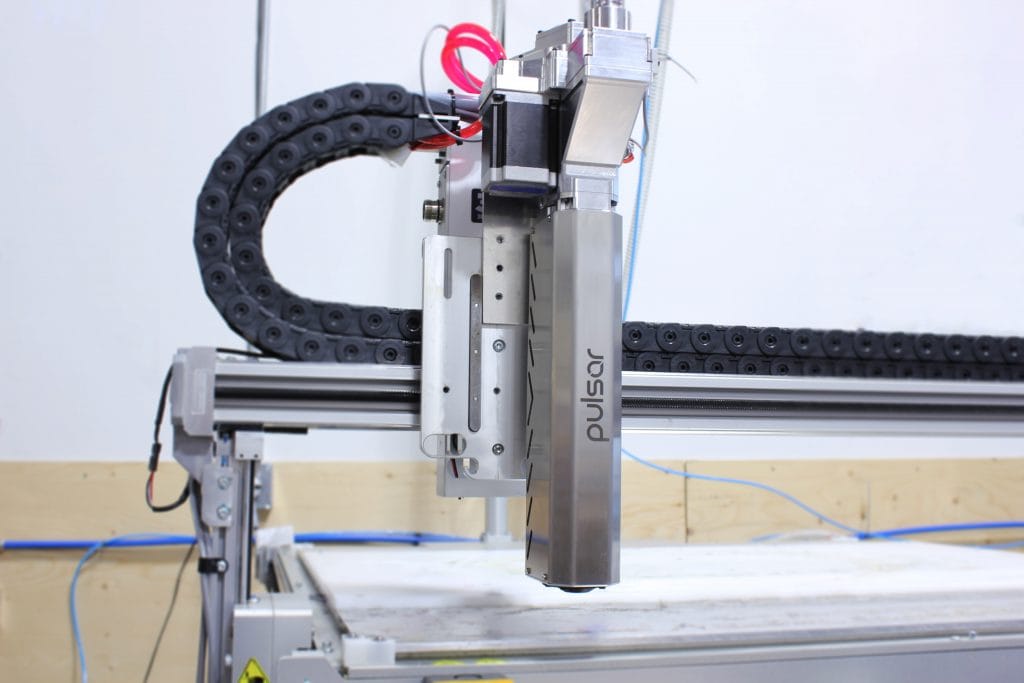

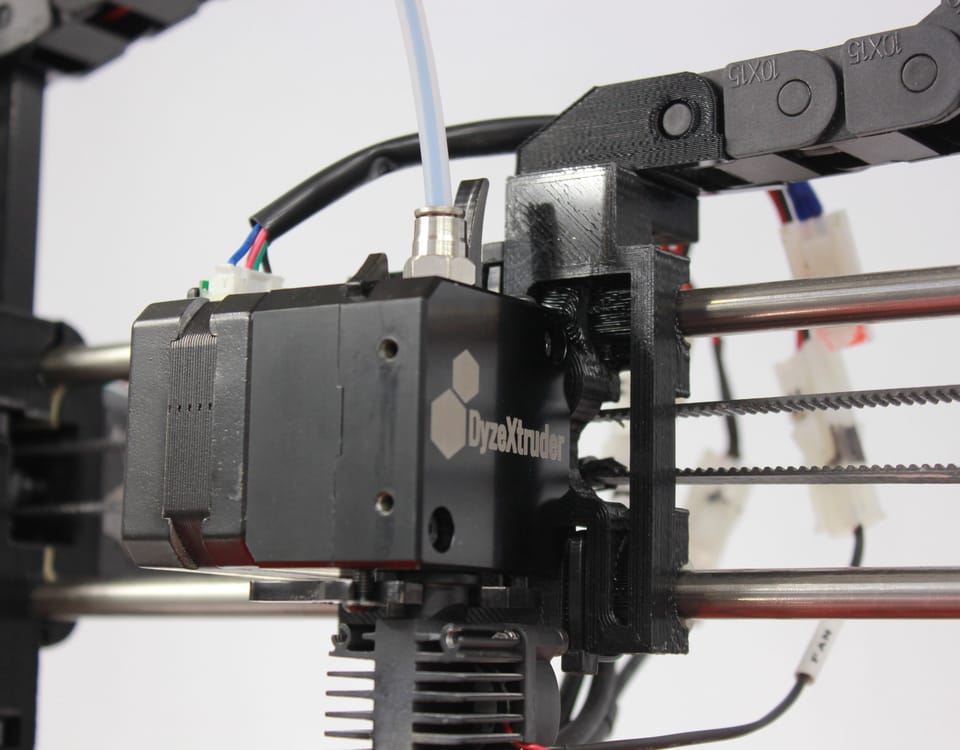

Learn to optimize your 3D printing with pellet extruders. This guide covers key steps for calculating screw speed, determining flow rates, and adjusting RPM for optimal results. Perfect for those transitioning from filament to pellets or enhancing pellet-based print precision. Dive in for practical tips and start fine-tuning your 3D printing process today.