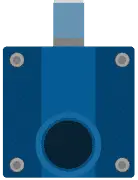

Extrudeur DyzeXtruder GT 1.75mm

CA$215.00

Extrudeur de haute qualité, tout en métal. Peut imprimer tout type de matériaux. Force de poussée élevée et double système d’entraînement par pincement.

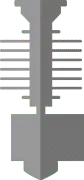

Metal Reduction Gears

The DyzeXtruder GT has a 5.65 : 1 gear ratio. This ratio has been chosen to use the full potential of a very small motor while, enabling very high pushing forces.

The gears are custom made from high strength hardened steel and brass. This combination allows low friction operations and a longer life. The gears and bearings are designed to last for hundreds of kilograms in extreme conditions.

Optimized spring

Spring tension is a key factor to a good and reliable extruder. Having the ability to adjust the tension present several challenge.

Applying too little pressure causes the filament to grind before the motor reaches its full potential. However, applying too much pressure causes the motor struggles against friction, inducing filament deformation, and losing torque that would otherwise be available to push the filament.

Adjusting the pressure from a spool to another can also yield inconsistent results.

Dual pinch drive system

The dual-pinch system allows a higher pushing force with a lower filament pressure. It reduces the risk of flattening the filament when highly detailed prints require a lot of retractions.

High pushing force

The combination of reduction gear, dual pinch and unique design enables the DyzeXtruder GT to push as much as 9 kg (20 pounds) of force. This is more than necessary for all 3D printing applications.

Easy filament removal and insertion

The unique lockable lever makes filament change very easy and convenient. The locking mechanism holds the lever in position while you change the filament. After, simply push back the lever to disengage the locking mechanism.

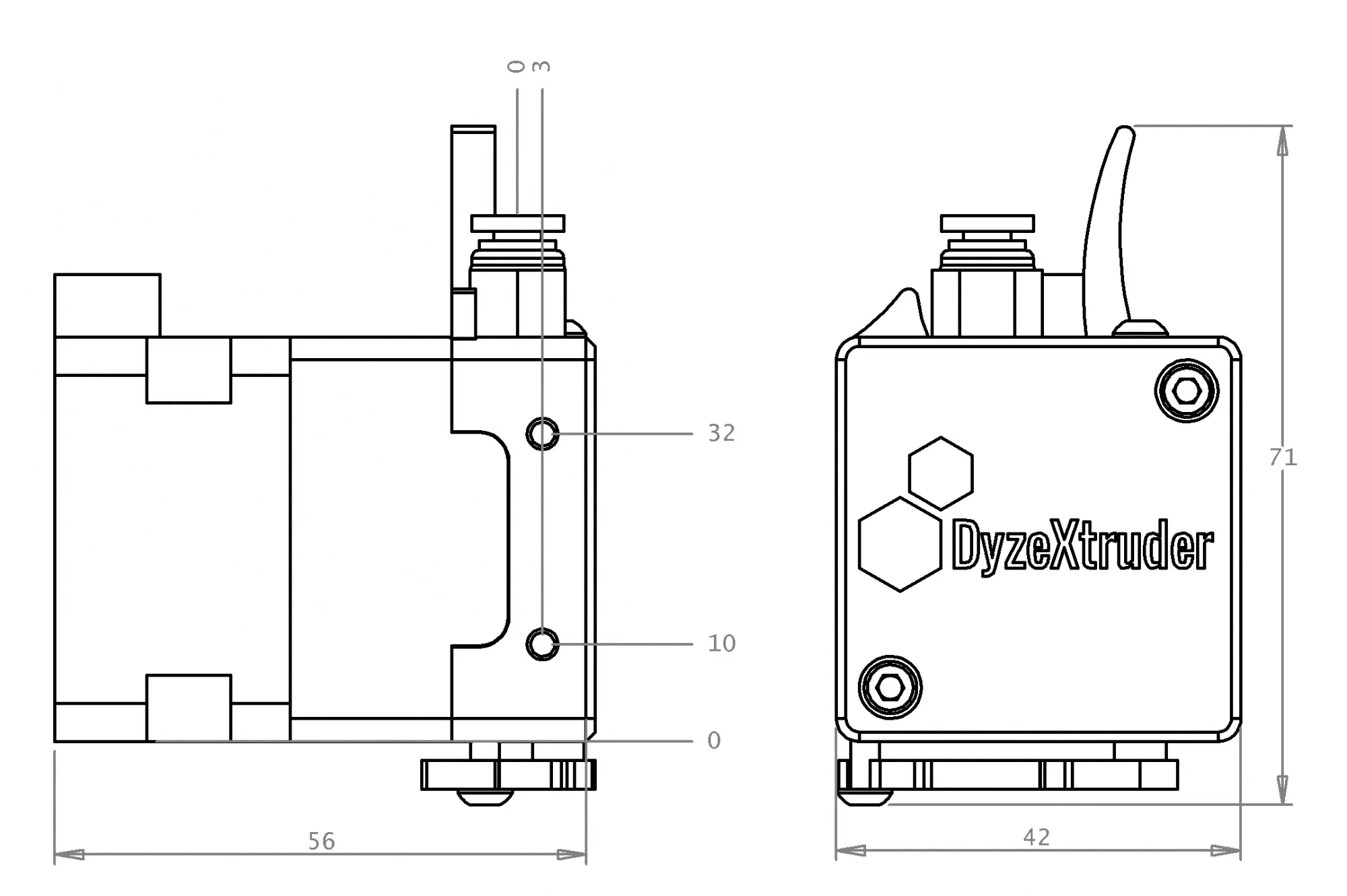

Small form factor

The DyzeXtruder GT is not larger than the NEMA 17 it uses, making it very space efficient on a multiple extruders configuration. Saving space on a carriage can allow you to print larger parts on a single printer.

Lightweight

The gear ratio was chosen to get the best of a very small motor.The DyzeXtruder GT is a lot lighter than a traditional extruder with a planetary gearbox, allowing for faster printer accelerations.

All metal

The aluminum housing is designed to offer a reliable operation, even in a high temperature environment.

Clean pinch system

The unique tooth profile allows a 4-contact point on the filament, increasing even more the maximum pushing force. Combined with the dual pinch drive, it can unlock the full potential of a geared motor and prevents any damage to the filament during printing.

Assembled and tested

The DyzeXtruder GT is a high-end product and comes preassembled and tested; thus ensuring users won’t receive substandard parts that are hard to assemble or fit together.

Flexible filament ready

The filament is very well guided inside the DyzeXtruder GT’s main frame, which allows very high speed with flexible filaments. The unmatched design prevents any flexible filament from leaking inside the mechanism. The drive system allows a superior filament alignment between the teeth for optimal prints.

Bowden ready

The DyzeXtruder GT always comes with a special push to connect fitting. APTFE tube can be inserted through the connector to guide the filament as far as possible inside the mechanism. A single modification in the firmware can easily transform a direct drive setup into a bowden.

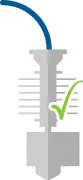

Easy hotend swapping

The hotend locking mechanism is very practical and rigid.You can secure the hotend in place with only a screw. You can remove it even if there is still a filament inside the extruder due to its turning mechanism. No more hassle of disassembling your setup when you need to maintain your printer.

Easy to mount

The side mounting threads make it very easy to assemble; only two M3 screws are needed to fit the DyzeXtruder GT in a printer.

Liquid cooling ready

The DyzeXtruder GT can be easily converted to a liquid-cooled setup with Dyze Design’s specialized cooling blocks.

DyzEND-X ready

The DyzeXtruder GT is optimized to work perfectly with Dyze Design’s DyzEND-X hotend. The best results are achieved when pairing these two products.

Connectors

The DyzeXtruder GT comes with connectors for its motor so you can easily maintain it.

Any Plastics

The DyzeXtruder GT prints all types of plastics:

- Standard: PLA, ABS

- Flexible: TPE, TPU

- Support: PVA, HIPS

- Advanced: PC, PET, PETE, PETG, NYLON

- Engineering: PEEK, PEI

- Metal powder filled

- Wood filled

- Carbon fiber filled

Download PDF Specsheet Download 3D CAD DyzeXtruder Support

| Parameter | Value | Units |

| Weight | 275 | g |

| Filament diameter | 1.75 | mm |

| Operating current | 1 | A |

| Operating temperature (air cooled) | 0 to +60 | °C |

| Operating temperature (liquid cooled) | 0 to +120 | °C |

| Top fitting tube OD | 4.00 | mm |

| Gear ratio | 5.65 : 1 | |

| Groove mount head thickness | 2 – 5 | mm |

| Mounting screw thread | M3 | |

| Mounting screw min thread depth | 5 | mm |

- DyzeXtruder GT

- 1000mm stepper motor cable

- 2* M3x10 mounting screw

- DyzeXtruder and Dyze Design Stickers

Afficher les commentaires dans toutes les langues (1)

Produits similaires

-

Kit DyzEND-X + DyzeXtruder GT 1.75mm

Note 5.00 sur 5CA$315.00 – CA$339.00Plage de prix : CA$315.00 à CA$339.00Kit Extruder & Buse de Dyze Design: Impression haute température et rapide avec force de poussée élevée.

Choix des options Ce produit a plusieurs variations. Les options peuvent être choisies sur la page du produit -

Tête Chauffante DyzEnd-X 1.75mm

CA$122.00 – CA$147.00Plage de prix : CA$122.00 à CA$147.00Tête Chauffante Haute température et Rapide pour imprimante 3D.

Choix des options Ce produit a plusieurs variations. Les options peuvent être choisies sur la page du produit

Avis

Il n’y a pas encore d’avis.