The Pro series line of product is designed to push the reliability to a whole new level. Every small feature has been redesigned from bottom-up from based on the feedback we received and our own experience.

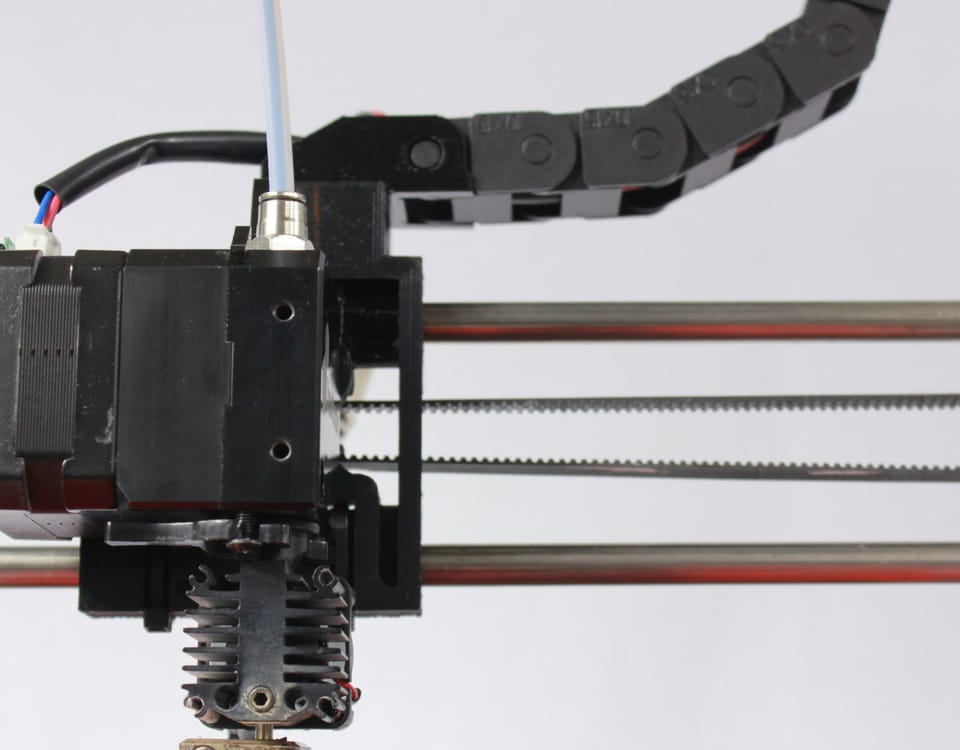

The 3d printer hotend’s heater block undergoes a massive amount of stresses: thermal stress from the heater, pressure stress from the extruder and tension stress from the nozzle. With our intensive tests with high-temperature materials such as PEEK, PEI (Ultem) and PSU, we have realized that this component required a rethinking.

Heater Blocks with apparent signs of stress

Understanding materials

The first step when designing a part is to choose the right material. There are a ton of different alloys available out there, and they all have their advantages and application. When choosing, you need to identify the key characteristics you’ll be evaluating. In our heat block case, we’ll want:

- Mechanical properties at high temperature

- Thermal conductivity

1. Mechanical properties

Mechanical properties are used to compare performance in different situations between materials. There are dozens of different types: hardness, fatigue, etc. The most common property is the tensile strength. It is measured by loading a specimen by stretching it. A lower tensile strength means less force is required to break.

Once the tensile strength limit is reached, the part will either deform, shear or break. In all case, it won’t be usable anymore.

2. Alloys

Alloys are recipes made from metals and other materials designed to increase properties. Corrosion, hardness, strength and many others. However, adding alloying elements will generally lower both the thermal conductivity and electrical conductivity.

Pure iron has very little use as it is very soft and weak. Adding as few as 0.15% to 0.80% carbon will make it a steel, which is much stronger. Adding chromium (and nickel) will make a stainless steel. When comparing thermal conductivity between our recipe evolution, we started at around 80 (W/mK) for iron, down to 50 with steel, down to 15 with stainless steel.

Increasing mechanical properties has a price, and thermal conductivity is often reduced as shown before. Other properties also suffer from adding alloying elements, such elongation at break, ductility, and few others.

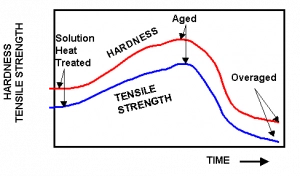

3. Heat Treatments

This process is used to modify and enhance some mechanical properties such as tensile strength and hardness. Most alloys are still weak without heat treatment. It is very important to understand the mechanisms of tempering an alloy. Heat can reverse most temperings, keep this in mind.

The process is quite unique for steel, as it is the only one who benefits from a rapid cooling.

Other alloys require an aging process or cold working rather than a quenching process. A high temperature is held for a certain amount of time, then the part is slowly cooled. The part can later be stretched or hammered to increase strength even further.

Care must be taken when choosing a material when it has an aging process. Running it at high temperature will continue the aging process and bring back the mechanical properties to the original “O” state. This will be further explained later.

4. Thermal properties

As the heat block is designed to transfer the heat from the heating source, the heater cartridge, to the polymer, it’s important to do this efficiently. Two major properties are interesting in our application:

- Thermal conductivity

- Specific heat

It is very important to understand that doubling the thermal conductivity won’t double any performance at all in 3D printing. A higher thermal conductivity will have a much bigger impact on a long and wide part, such as a heat sink. As the heat block transfer heat between a few millimeters between the heater and the nozzle, the difference is not noticeable from a 3D printing performance point of view.

Melting Temperature

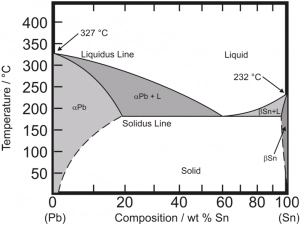

One thing is sure, you want your filament to melt, not the heat block. As mentioned before, adding alloying element have some drawback. In this case, most alloys will have a lower temperature than the base material, up to a certain percentage.

We can see this behavior on what we call a “Phase Diagram”. From left to right, you can see the evolving melting (liquidus – solidus) temperature from 100% lead to 100% tin.

Another important fact about this diagram is that alloys have a solidus line different than the liquidus line. It simply means that between those regions, you have a “slushy” material, meaning that both solid and liquid states are presents. Quick spoil, a slushy heat block won’t work, so you have to check the solidus line for the ultimate temperature.

Thermal Creep

Thermal creep is not to be confused with “heat creep” commonly used in 3D printing community. Heat creep is more related to heat conductivity in the filament where heat will climp up to the cold zone. Thermal creep occurs when a material has been exposed for a long time to a high temperature and stress. The material will slowly relax and deform over time, even if the stress is under a safe security factor.

Choosing the right material

Based on this knowledge, we are able to analyze the following materials in order to find which one is best suited for our application.

1. Aluminum

Aluminum is without any doubts the most widely used material for heat blocks. It has good thermal conductivity, low density, low cost, low machining cost.

Through its first phase of hardening, the 6061 alloy is heated to 500°C during 9 to 10 hours to get a single phase alloy, meaning that all added elements are dissolved in aluminum. Then it is aged at 180°C for the same amount of time. There is a problem when considering using this material for a heat block as the printing temperature is within the aging range. This will slowly bring the alloy back to its base temper, which reduces the tensile strength from 270 MPa to 76 MPa at room temperature.

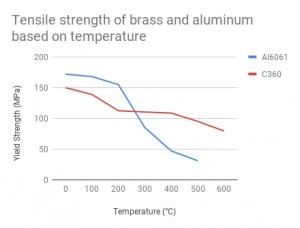

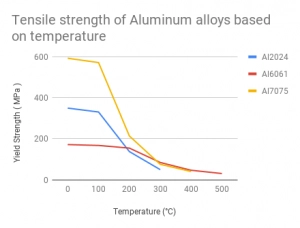

Other aluminum alloys such as the high strength 2024-T4 or 7075-T6 have similar aging temperatures, which bring the same design problems. The table below shows the mechanical properties based on temperature. The general purpose aluminum performs better than 2024 from 200°C and better than 7075 from 300°C.

2. Brass

Mostly known as the nozzle material, brass has some advantages compared to aluminum. It has a very similar thermal conductivity and is easy to machine. However, the price is a little higher due to the high copper content.

Brass should have a significant advantage over aluminum. The tempers offered with typical brass (C360 brass) are cold working and shouldn’t be affected by aging the same way as aluminum. However, a new problem will occur and it is called recrystallization. When brass is cold worked, the grains are stretched, squeezed and deformed. This significantly increases the mechanical properties. However, the recrystallization starts happening between 200°C and 300°C, which replace the “forged” grains with standard new ones. These new grains have reduced mechanical properties.

Despite this behavior, the common C360 brass alloy would still be a better choice than any aluminum alloy. Below is a comparison with 6061 aluminum.

3. Copper

Copper is getting more and more popular as a heat block material. This material has one main advantage, it is an excellent thermal conductor. However, as we explained before since the distance heat has to travel is very short, this won’t be beneficial for the end user.

Copper alloys have the same problem as aluminum regarding precipitation hardening. After only 5 hours at 370°C, the aging process has already reduced the mechanical properties by 25%.

Pure copper can’t be precipitation hardened as there are no alloying elements. The behavior is very similar to brass, where cold-working tempers are required to increase mechanical properties. Similar to brass, copper suffers from recrystalisation. In this case, the temperature is a little higher, starting at around 270°C.

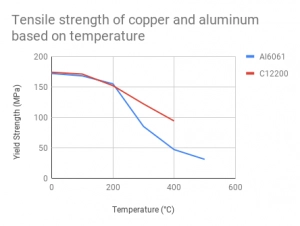

In contradiction with popular belief, copper has no real advantages over aluminum for high-temperature application as shown below. Brass is actually a much better choice.

4. Steel

This material is less popular in the 3D printing community, but you’ll soon realize that this alloy has interesting properties for a heat block. It’s affordable, harder to machine than brass and aluminum, and has no corrosion resistance. However, steel is very strong and can endure high temperature.

To modify the grain structure, the steel needs to be heated to what we call austenitizing temperature, which is around 725°C.

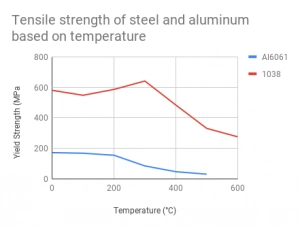

As you can see on the graph below, steel is well adapted for high temperature and more than 3 times stronger than aluminum.

DyzEnd Pro

Now that you have seen the properties and comparison of materials, it is easier to understand our decision. For a long-term use in high temperature, brass, copper, and aluminum will lose their strength. Sometimes, it can happen within a few hours of print, depending on the temperature.

However, checking the literature is never sufficient for a design. We have done tests with heating time, nozzle temperature, extrusion performance and print quality with 3 heat blocks: aluminum, copper, and steel. The only difference we have observed it that both steel and copper took a little bit more time to heat than aluminum. Extrusion, nozzle temperature, and print quality were all the same.

For high-temperature material, steel is the way to go. With a massive 330 MPa at 500°C, a steel heat block will handle any filaments without any risk.

For rust protection, we opted for the widely used electroless nickel plating. It looks great and it’s very easy to keep clean, thanks to the low friction nickel-phosphorus alloy properties.