Choosing the right extruder for your 3D printing needs can be a daunting task, especially with the range of options available.

Dyze Design offers a variety of extruders for both desktop and high-flow printing applications.

In this blog post, we’ll break down the differences between each of the four extrusion systems available – the DyzeXtruder GT & Dyzend-X hotend, DyzeXtruder Pro & Dyzend Pro, Typhoon™ 2.85 mm filament extruder, and Pulsar™ pellet extruder.

We’ll explore the benefits of each one, so you can make an informed decision when selecting the extruder that best fits your needs.

Our Extrusion Systems

We have two main extrusion systems categories at Dyze: our “desktop” product line which fit on a smaller size 3D printers, and our « high-flow » extruders which fit on larger printers for large-scale additive manufacturing applications (LSAM).

You can find more information on each product by visiting the links below:

- The GT series (DyzeXtruder GT & Dyzend-X)

- The PRO series (DyzeXtruder Pro & Dyzend Pro)

- Typhoon™ filament extruder

- Pulsar™ Pellet Extruder

What is the main difference between them?

| GT Series | Pro Series | Typhoon™ | Pulsar™ | |

|---|---|---|---|---|

| Material type | Filament | Filament | Filament | Pellet |

| Material size | 1.75mm | 1.75mm | 2.85 mm | 3mm-5mm |

| Printer type | Desktop printer | Desktop printer | Large scale printer | Large scale printer |

| Robotic arm | No | No | Yes | Yes |

| Max printing tempetature | 500°C | 500°C | 450°C | 500°C |

| Nozzle size (mm) | 0.4; 0.6; 0.9; 1.2 | 0.4; 0.6; 0.9; 1.2 | 0.6; 0.9; 1.2; 1.8; 2.5 | 1; 1.5; 2; 3; 4; 5 |

| Max flow (mm³/s)* | 25 | 25 | 200 | 500 |

| Max flow (g/h)* | – | – | 0.9 | 2.5 |

| Weight (g) | 327 | 352 | 1750 | 7000 |

| Starting price (CAD) | 300$ | 430$ | 3 150$ | 10 850$ |

*Variable depending on the type of filament (see our documentation for more information)

Desktop Extruders

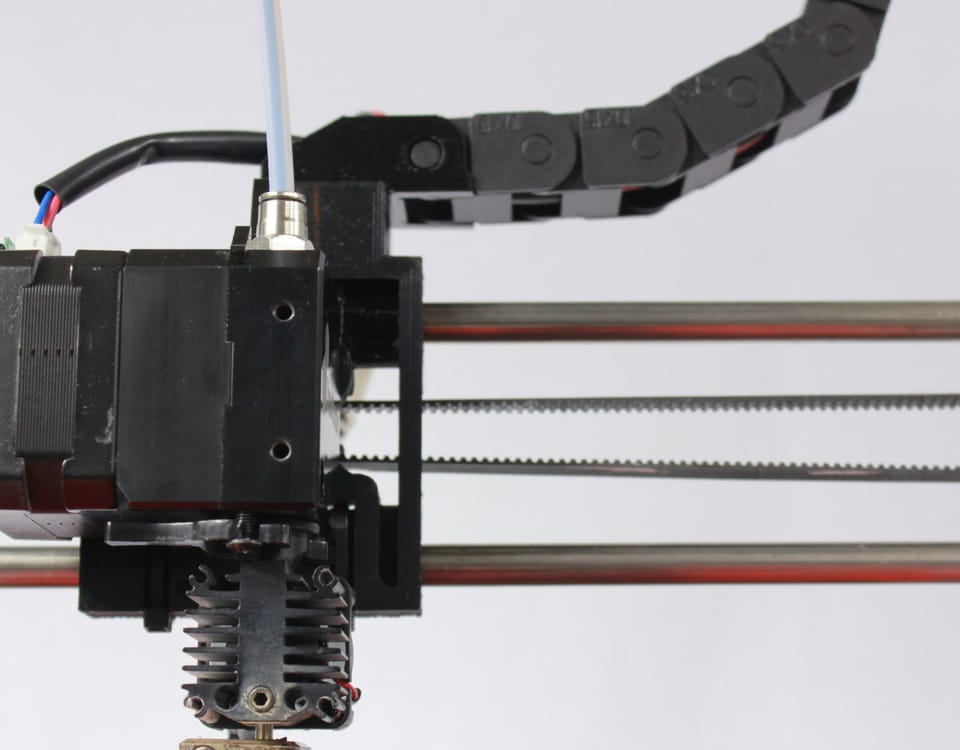

There are two models of extruders and hotend for desktop 3d printers offered by Dyze Design:

the GT series and the Pro series.

Both of them can be integrated into any printer whose firmware can be modified (i.e. Open-Source 3d printers).

Here’s the information about the firmware modifications that would be required to use the extruders or hotends:

https://docs.dyzedesign.com/hotends.html#firmware-configuration

https://docs.dyzedesign.com/extruders.html#firmware-configuration

The main difference between the Pro and the GT is that the Pro series boasts increased overall performance in terms of flow rate and feedrate with advanced material such as flexibles. Also, the traction wheels material used for the Pro series is an improved alloy with added plating, which allows better resistance than the GT version.

Moreover, the GT series came with a stainless steel nozzle whereas the Pro series comes with a tungsten carbide nozzle.

High Flow Extruders

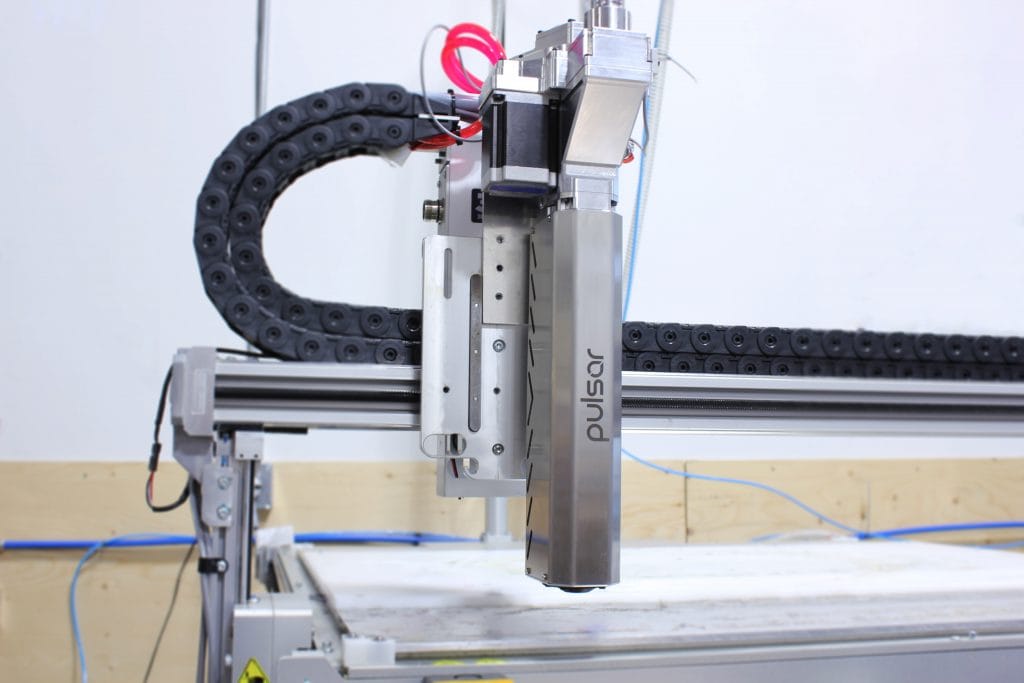

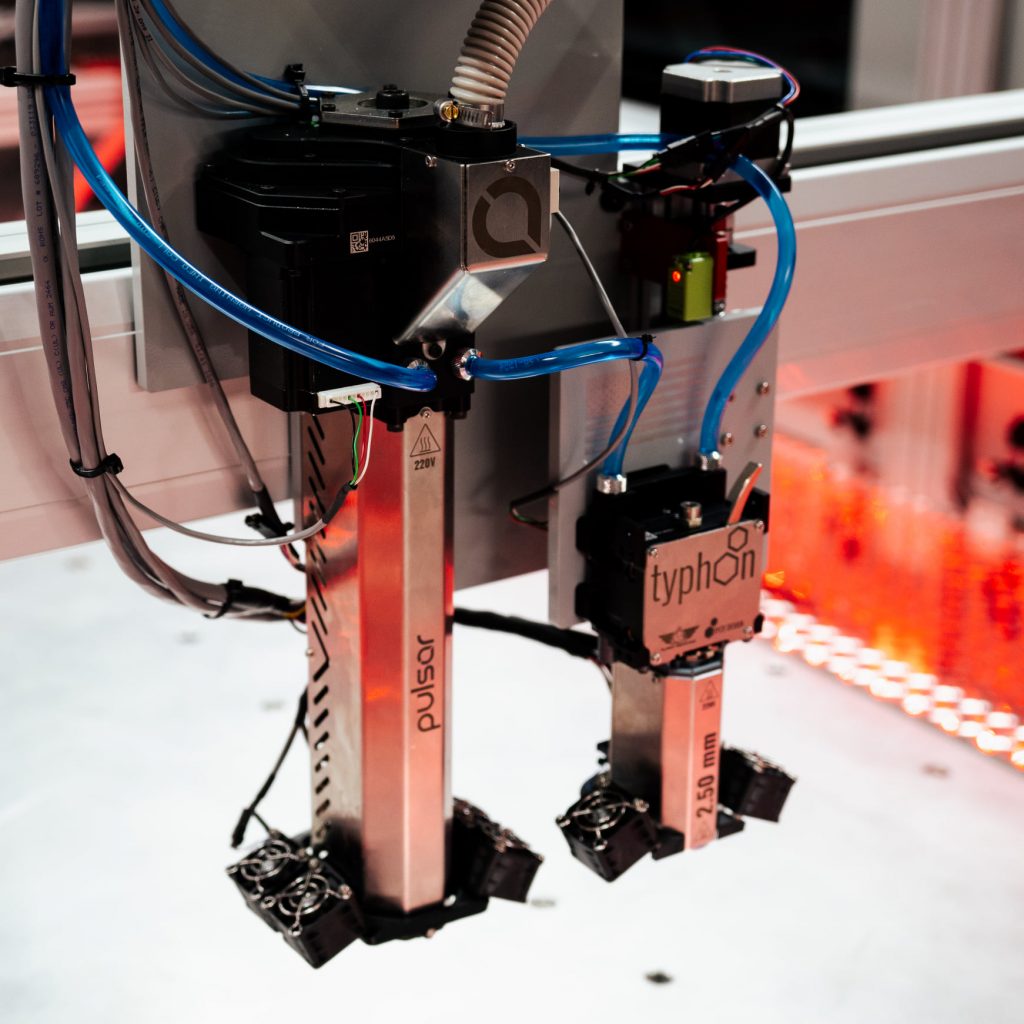

Typhoon™ and Pulsar™ are both high-flow extruders from Dyze Design. Both of them could be mounted on robotic arms or large format 3d printers (more than 1 m³ build volumes).

The main difference between them is that Typhoon™ is a filament extruder using a 2.85 mm filament and the Pulsar™ is a pellet-based extruder.

Typhoon™

The Typhoon™ is a 2.85 mm filament extruder. It can output up to 200 mm³/s and has nozzles ranging from 0.6mm to 2.5mm, so it’s able to print with many details but also prints faster with fewer details.

If you want an extruder that can print in high resolution while keeping fast print times, Typhoon™ is the one for you.

Why choose the Typhoon™:

- Use filaments

- High-resolution prints

- 8X faster than the desktop extruder

For more information about the Typhoon™, visit the product information page here: https://dyzedesign.com/typhoon-extruder/

Pulsar™

As a direct pellet (granules) extruder, the Pulsar™ prints way faster than any other extrusion system and lets you save a ton of money on material cost, as pellets are 6 to 10 times cheaper than filament. There are multiple nozzles size on the Pulsar™: 1 mm, 1.5 mm, 2 mm, 3 mm, 4 mm and 5 mm.

Why choose the Pulsar™:

- The low weight (7kg) allows it to be put on a low payload robotic arm

- Very fast printing (2.5kg per hour)

- Large possibility of material

- Use pellets (reduce the cost of material)

- Anti-oozing system that reduces oozing, allows multi-part print and not only « vase mode » printing.

The Pulsar™ extruder is the best choice when printing large prints in the shortest amount of time.

For more information about the Pulsar™: https://dyzedesign.com/pulsar-pellet-extruder/

What to choose?

In conclusion, selecting the right extruder for your 3D printing needs is an important decision that can impact the quality, speed, and cost of your prints.

Dyze Design offers a range of extruders for both desktop and high-flow printing applications, with each extrusion system having its unique features and benefits.

The desktop extruders, GT series and Pro series, are ideal for smaller-sized 3D printers, while the Typhoon™ and Pulsar™ are designed for larger printers and high-flow printing applications. The Typhoon™ offers high-resolution prints, while the Pulsar™ is the best choice when printing with pellets to reduce material costs.

By considering the differences between each extruder, you can make an informed decision and choose the best one for your specific printing needs.