This strategic partnership aims to enhance precision, speed, and quality in 3D printed prosthetic sockets with Dyze Design’s new advanced industrial motion I/O controller.

MONTREAL, QC, September 09, 2024 – Filament Innovations, a leading Pennsylvania-based OEM specializing in additive manufacturing machines for the Orthotics and Prosthetics (O&P) industry, has entered into a strategic partnership with Dyze Design. This collaboration aims to streamline the manufacturing of 3D-printed prosthetic sockets by integrating Dyze Design’s upcoming state-of-the-art Aurora™ industrial motion I/O controller, equipped with cloud connectivity and real-time data collection.

By leveraging Dyze Design’s latest cutting-edge technology, Filament Innovations will enhance the performance of its machines, enabling more precise motion control, real-time sensor data logging, and advanced in-situ part analysis. This will result in improved production speed, accuracy, and quality for prosthetic socket fabrication, meeting the demanding requirements of the O&P industry.

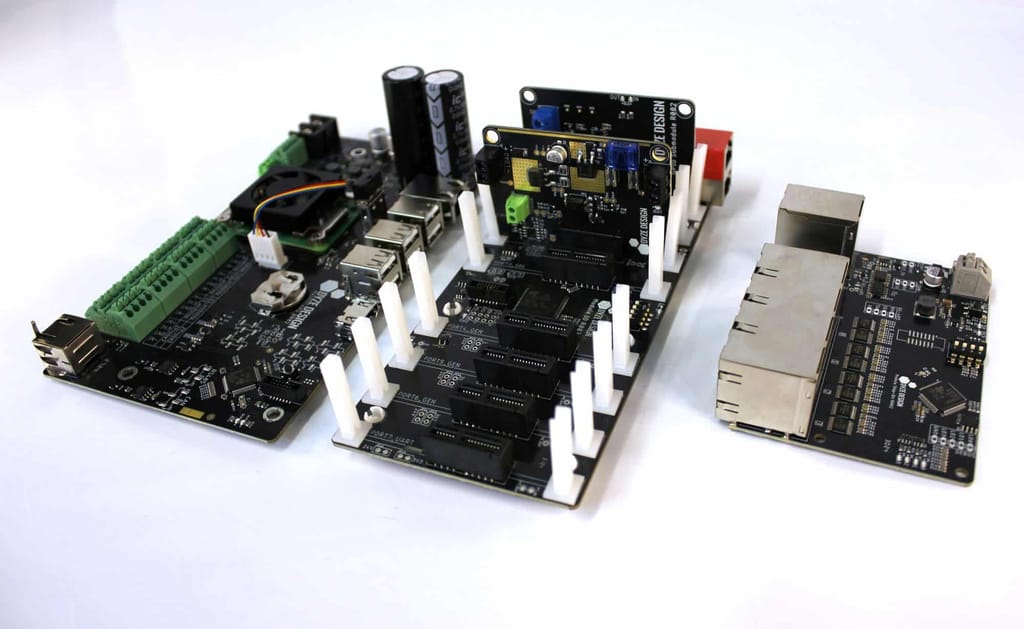

“We developed Aurora to address the limitations of current motion control systems, also known as 3D printer mainboard or 3D printer controller, especially the lack of real-time data feedback and sensor support,” said Philippe Carrier, CTO of Dyze Design. “With Aurora, machine manufacturers or 3d printing operators can increase throughput, receive immediate feedback, and rapidly resolve issues, all while maintaining affordability compared to more traditional industrial controllers, like PLCs. This marks a major step forward in making additive manufacturing a truly viable solution for large-scale, end-use industrial applications.”

Aurora™ is designed specifically for industrial users and professionals in additive manufacturing. After four years of meticulous development, it introduces advanced capabilities such as a 2-stage position feedback system, real-time data logging, and in-process & post-process part analysis. These features empower users to visualize, validate, and optimize their production processes, significantly reducing the risk of print failures and improving repeatability for part production.

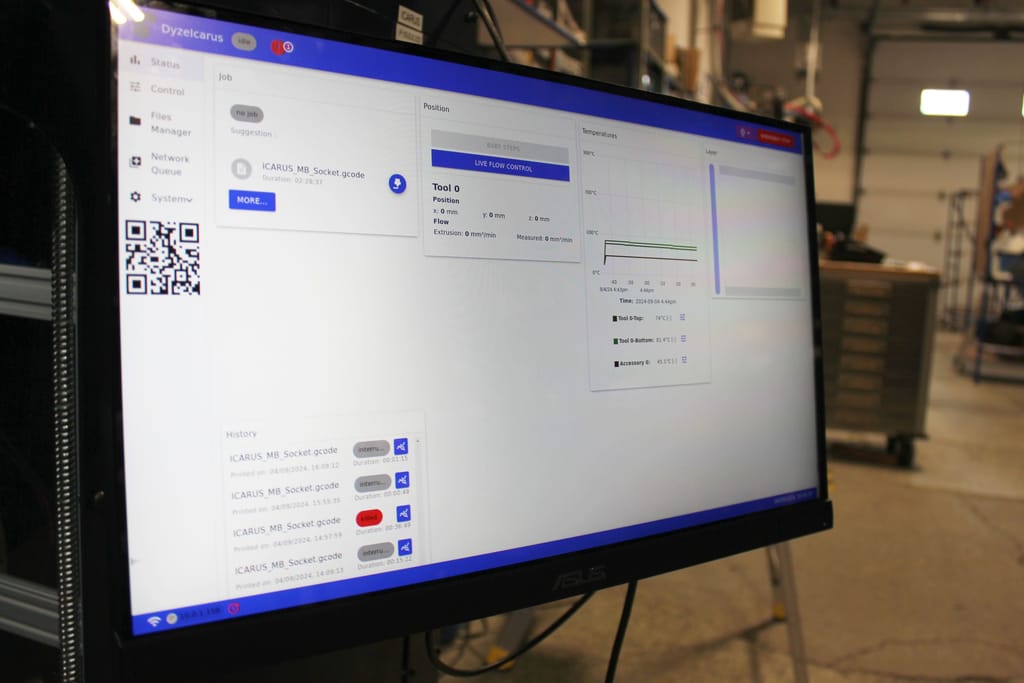

Dr. Michael Gorski, MBA, PhD & CEO of Filament Innovations, added, “This partnership enables us to offer a best-in-class solution for prosthetic socket production, which is critical in our mission to provide high-quality, custom-fit prosthetics quickly and efficiently. Dyze Design’s technology helps us meet the evolving needs of our customers and the O&P industry at large. Filament Innovations has over nine years of experience building 3D Printers, that means we have nine years of experience of working with customers to understand what they want from an OS. We were able to work with Dyze Design to create the OS, machine control system, and interface that customer’s actually want to work with. With the Aurora system we can now produce validation reports of the printed object, have a streamlined user interface, and overall have a “push button, get result” OS that our customers want on their machines. This control system will push 3D Printing into the next stage of it’s life cycle because it is solving a real problem – give the customer’s what they want in a 3D Printer”.

The Dyze Aurora’s journey began in 2020 with a vision to integrate new sensor types into 3D printing extrusion systems, also known as printheads or tool heads. Over time, this vision expanded, evolving into a full motion controller ecosystem that not only includes advanced sensor capabilities but also comprehensive data logging and visualization features to provide in-situ monitoring, setting a new standard in machine control and performance.

The collaboration between the two corporations reflects their shared commitment to innovation and to advancing the capabilities of additive manufacturing in the healthcare sector. As more industries adopt 3D printing for specialized applications, the integration of smart motion controllers like Aurora™ will be instrumental in improving overall part quality and production efficiency in Additive Manufacturing.

From September 12 to 15, 2024, Filament Innovations will showcase this brand new technology at the American Orthotic and Prosthetic Association (AOPA)’s Ignite 24 event. Aurora™ will be integrated into Filament Innovations’ ICARUS platform, alongside Dyze’s latest precision pellet extruder, Pulsar Atom. Visit booth 745 to see it in action.

About Dyze Design

Founded in 2015 and headquartered in Montreal, Quebec, Canada, Dyze Design is dedicated to empowering individuals and industries to create the tools and products they need, precisely when and where they need them. Specializing in high-quality and high flow extrusion systems, both for Fused Filament Fabrication (FFF) and Fused Granulate Fabrication (FGF), advanced sensors, accessories, and innovative control systems and software, Dyze Design is recognized for its commitment to high reliability and exceptional performance.

Serving primarily industrial clients with specialized applications, Dyze Design stands out for its advanced solutions that enhance the quality and precision of 3D printed parts. With a focus on pushing the boundaries of what’s possible in 3D printing, Dyze Design continues to lead the way in advanced manufacturing technologies.

About Filament Innovations

Filament Innovations specializes in additive manufacturing machines dedicated to the O&P industry. The company focuses on producing 3D-printed prosthetics with unmatched quality, speed, and customizability.

Media Contact

Simon Duchaine

Co-Founder & Chief Commercial Officer

Dyze Design

Phone: +1 (438) 238-1400

Email: [email protected]

Website: www.dyzedesign.com